Introduction to Induction Forging Furnaces

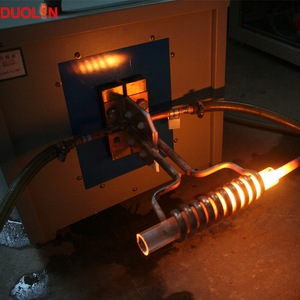

Induction forging furnaces are pivotal in the metallurgical industry, providing a modern method to heat and melt metals for forging and casting. The induction forging furnace 80kw is a specific category within this technology, designed for efficiency and precision in heating processes.

Understanding the 80kw Induction Forging Furnace

The 80kw induction furnace is engineered for the melting of various metals, including iron, aluminum, and copper, as well as precious metals like gold, silver, and platinum. Its capacity to reach temperatures from 1,750 to 2,100 degrees Celsius makes it versatile for different metallurgical tasks. The technology behind these furnaces utilizes electrical induction to generate heat, coupled with hydraulic systems to manage the tilting of the melting pot.

Features of Induction Forging Furnaces

An induction melting furnace is characterized by its melting speed, typically ranging from 40 to 60 minutes depending on the metal and furnace type. The tilting mechanism, often capable of reaching up to 95 degrees, ensures complete pouring of molten metal. Moreover, the inclusion of large capacitor banks stabilizes the current, enhancing the safety and efficiency of the operation.

Design and Safety Aspects

Safety is paramount in the design of an induction heating furnace. Features such as well-insulated capacitors and integrated circuit breakers are standard to prevent accidents and equipment damage. Additionally, water-cooling systems are incorporated to manage the high temperatures involved in the melting process.

Operational Control in Induction Furnaces

Control systems are a critical component of an induction furnace for forging. A Programmable Logic Controller (PLC) is commonly employed to manage the furnace's operations, ensuring precision and repeatability in the forging process. This level of control is essential for maintaining consistent quality in metalworking.

Choosing the Right Induction Forging Furnace

Selecting an appropriate induction forge furnace is crucial for meeting specific industrial needs. While the 80kw model serves a broad range of applications, the requirements of the task dictate the suitability of the furnace. Alibaba.com hosts a diverse array of these furnaces, facilitating the connection between buyers and reputable suppliers without endorsing any particular brand or making promotional claims.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4