Full-automatic Disposable Slipper Making Machine Nonwoven Shoe Hotel Slippers Making Machine

Fruit Packing Machine Auto Drie Fruit Flow Wrapping Machine Bafu Cake Cookies Biscuits Packing Machine

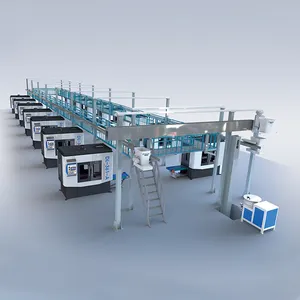

Faucet Full Production Line With Sand Core Making Gravity Casting Automatic Polishing Machining Line

Disposable Slipper Cutting Machine 50 Tons Hydraulic 4 Column Disposable Slippers Die Press / Cutting Machine /die Cutting Machine

Automotive Door Window Rubber Seals Trim Seal Weather Strips Making Machine Production Line

Forbona Sell Well New Type Fully Automatic 1200pcs/min Disposable Cotton Swab/Cotton Buds Making Machine

High Speed Hotel Luxury Slipper Linen Cotton Custom Logo Printing Machine Disposable Luxury Slippers Making Machine

Smart Full Automatic Disposable Slipper Production Line Hotel Shoes Making Machine

Full-automatic Disposable Slipper Making Machine Nonwoven Shoe Hotel Slippers Making Machine

Fast Speed Full Auto Hotel Use Disposable Slipper Making Machine

Non Woven Soft Slipper Production Line Custom Logo Disposable Hotel Slipper Making Machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4