Introduction to Hot Forging Machines

Welcome to Alibaba.com, your premier destination for hot forging machines. In this section, we will provide you with valuable insights into the world of hot forging machines, their types, applications, features, and advantages. Whether you are looking for a hot forging machine for your business or industrial needs, you've come to the right place.

Types of Hot Forging Machines

Hot forging machines come in various types, each designed to cater to specific forging requirements. Some common types include:

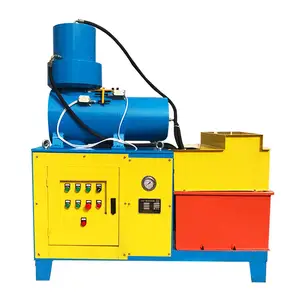

- Hydraulic Hot Forging Machines: These machines utilize hydraulic power to exert force and shape the metal. They offer precise control and are suitable for complex forging processes.

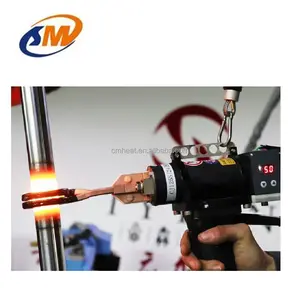

- Electric Hot Forging Machines: Powered by electricity, these machines provide efficient and consistent performance. They are known for their energy-saving capabilities and are ideal for medium to large-scale forging operations.

- Pneumatic Hot Forging Machines: These machines employ compressed air to generate force for forging. They are versatile, cost-effective, and widely used in small to medium-sized forging applications.

Applications of Hot Forging Machines

Hot forging machines find extensive applications across various industries. Some notable applications include:

- Automotive Industry: Hot forging machines are used to manufacture critical automotive components such as crankshafts, connecting rods, and gears.

- Aerospace Industry: These machines play a vital role in producing aerospace components like turbine blades, landing gear parts, and structural components.

- Heavy Machinery: Hot forging machines are utilized in the production of heavy machinery parts, including gears, shafts, and hydraulic components.

- Oil and Gas Industry: They are employed in forging components for oil rigs, pipelines, and drilling equipment.

Features and Advantages of Hot Forging Machines

Hot forging machines offer a range of features and advantages that make them indispensable in the forging industry. Some key features include:

- High Precision: Hot forging machines ensure precise shaping and dimensional accuracy of forged parts, meeting stringent quality standards.

- Efficiency: These machines operate at high speeds, enabling faster production cycles and increased productivity.

- Versatility: Hot forging machines can handle a wide range of materials, including steel, aluminum, and titanium, allowing for diverse forging applications.

- Durability: Built with robust materials and advanced engineering, these machines are designed to withstand heavy-duty usage and provide long-lasting performance.

By investing in a hot forging machine, you gain several advantages:

- Cost Savings: Hot forging machines reduce material waste and minimize the need for secondary machining, resulting in cost-effective production processes.

- Enhanced Strength: The hot forging process imparts superior strength and structural integrity to forged components, ensuring their reliability and longevity.

- Customization: Hot forging machines allow for the production of complex and customized parts, meeting specific design requirements.

Alibaba.com connects you with reliable suppliers offering a wide range of hot forging machines. Explore our extensive selection and find the perfect machine to meet your forging needs. Start browsing today and unlock the potential of hot forging technology for your business.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4