Introduction to Hardware PVD Coating Machines

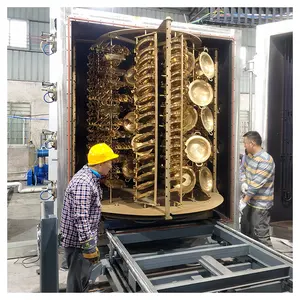

Physical Vapor Deposition (PVD) technology has revolutionized the metal finishing industry. A hardware PVD coating machine is at the forefront of this innovation, providing a sophisticated method for enhancing metal products. This category encompasses a range of machines designed for depositing thin films of various materials onto metallic substrates, offering both aesthetic and functional benefits.

Types of PVD Coating Machines

The realm of PVD coating is diverse, with each type of hardware PVD coating machine serving specific industry needs. Vacuum coating machines, for instance, employ a thin film deposition technique ideal for applications requiring precision and durability without the bulk of traditional coatings. On the other hand, machines designed for powder coating are adept at applying paint in powder form under high pressure, creating a uniform and resilient finish.

Applications and Features

PVD coating machines are integral to various sectors, including the creation of outdoor furniture and automotive components. The application of a PVD coating enhances a product's resistance to wear, corrosion, and weathering. Features of these machines include advanced control systems for precise coating thickness, temperature regulation, and customizable coating chambers to accommodate different product sizes.

Materials and Advantages

The materials used in PVD coatings range from metals to ceramics, each selected for its unique properties. The advantages of using a hardware PVD coating machine include extended product life due to increased hardness and oxidation resistance, as well as the machine's ability to coat complex shapes uniformly.

Choosing the Right PVD Coating Machine

Selecting the appropriate hardware PVD coating machine involves considering the substrate material, desired coating properties, and specific industry requirements. Alibaba.com's platform facilitates this selection by showcasing a spectrum of machines, each designed to meet different industrial challenges without endorsing any particular brand or making qualitative claims.

Environmental Impact and Efficiency

Modern hardware PVD coating machines not only enhance product performance but also prioritize environmental efficiency. These machines are engineered to minimize waste and energy consumption, aligning with contemporary eco-friendly manufacturing practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4