Harden Tools: An Overview

Harden tools encompass a broad category of equipment designed for durability and precision. These tools are crafted from robust materials like carbon steel and tungsten carbide, ensuring longevity and consistent performance. The term 'harden tools' primarily refers to the process of heat treating tool steels to enhance their strength and wear resistance, a crucial aspect in various industries.

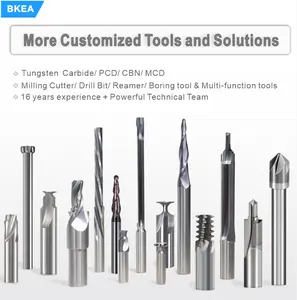

Types and Applications

The range of harden tools includes a variety of hand tools, from harden screwdrivers to harden hammers, each serving specific functions across different sectors. These tools are integral to tasks such as auto repair, industrial maintenance, and precision engineering. The versatility of harden tools is further exemplified by specialized items like the harden laser level and harden multimeter, which cater to the intricate needs of modern construction and electrical diagnostics.

Manufacturing Process

The manufacturing of harden tools involves sophisticated techniques like heat treating A2 tool steel and heat treat D2 steel, which are known for their impact resistance and edge retention. The process of heat treat tool steel typically includes hardening and tempering stages, where the metal is heated to a high temperature and then cooled rapidly during quench a blade operations. This treatment gives the tools their renowned hardness and resilience.

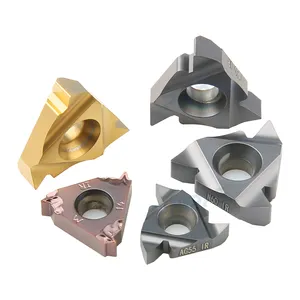

Material Advantages

Materials like A2 and D2 are frequently used in harden tools due to their robust properties. A2 steel heat treat procedures result in tools that withstand rigorous use, while heat treating D2 tool steel is known for producing instruments with high wear resistance. The choice of material significantly impacts the tool's application, with options like O1 steel heat treat offering a balance between hardness and toughness.

Features of Harden Tools

The features of harden tools are diverse, ranging from the precision of a harden digital multimeter to the brute strength of a harden axe. These tools are designed with the end-user in mind, ensuring that whether in a controlled environment like CNC milling or the variable conditions of external turning, the tool performs to its expectations.

Choosing the Right Harden Tools

Selecting the appropriate harden tool box or individual item is crucial for specific tasks. Factors such as the type of material to be worked on, the precision required, and the nature of the task itself should guide the selection process. While Alibaba.com does not manufacture these tools, it serves as a gateway for suppliers to offer a wide array of harden tools to meet the diverse needs of businesses.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4