Introduction to Frozen French Fries Machinery

The frozen french fries machinery category encompasses a range of equipment designed for the production of one of the world's most beloved snacks: french fries. This machinery is integral to the process of creating frozen french fries, offering solutions to enhance efficiency and meet the demands of a fast-paced food industry. From small-scale operations to large-scale production, these machines are pivotal in ensuring a consistent and quality product.

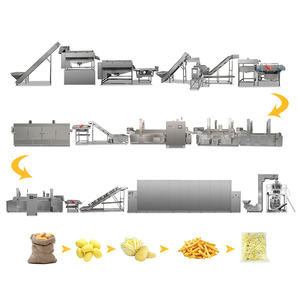

Types of Frozen French Fries Production Equipment

There are primarily two types of frozen french fries processing equipment: automatic and semi-automatic. The automatic machinery offers a comprehensive system, encompassing everything from washing and peeling to slicing, blanching, and frying. Semi-automatic machines, on the other hand, may require more manual intervention but still support the essential stages of production. The choice between these systems depends on the scale of operation and specific production needs.

Components and Features

A typical frozen french fries production line includes several key components. The initial stages involve a potato washing and peeling machine, followed by a slicer for cutting potatoes into the desired shape. Subsequent machines such as the blanching machine, dewatering machine, and fryer are crucial for texture and taste, while de-oiling and flavoring machines add the final touches. Each piece of equipment is designed to work in harmony, ensuring a seamless production flow.

Applications and Advantages

The application of frozen french fries equipment extends beyond just large factories. It is also suitable for smaller businesses and can be a valuable addition to restaurant kitchens. The advantages of using such machinery include increased production speed, uniformity in product size and quality, and the ability to meet large orders with consistency. Moreover, the machinery is designed to produce a product that caters to health-conscious consumers, reducing oil content without compromising on taste.

Material and Maintenance Considerations

Commercial french fry making equipment is typically constructed from durable materials like stainless steel, ensuring longevity and ease of cleaning. Maintenance is a critical aspect, as regular upkeep can prevent downtime and extend the machine's life span. While the specifics of maintenance will vary across different types of machinery, the common thread is the necessity for routine checks and cleaning to maintain optimal functionality.

Choosing the Right Machinery

Selecting the appropriate frozen french fries maker involves considering processing capacity, space availability, and the specific needs of your operation. Whether opting for a smaller capacity machine for a boutique business or a larger system capable of producing up to 2 tons per hour, it is essential to assess the efficiency and output requirements to make an informed decision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4