Introduction to Flat Coating Machines

Flat coating machines are integral components in the finishing industry, designed to apply a protective or decorative layer to flat surfaces. These machines cater to a variety of applications, from furniture and cabinetry to automotive parts, ensuring a consistent and even application of coatings.

Types and Applications

The versatility of flat coating machines is evident in their various types, such as powder coating machines and hot melt coaters. Each type serves distinct applications, ranging from enhancing the durability of metal components to providing an aesthetic finish to wooden furniture. Notably, these machines are adept at handling diverse materials like aluminum profiles, alloy wheels, and even flooring materials.

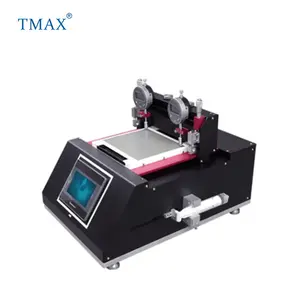

Features and Operation

Modern flat coating machines boast user-friendly interfaces, making them accessible to both novice and experienced operators. They come equipped with pre-set programs and customizable settings to meet specific coating requirements. The operational ease is complemented by features that promote a clean working environment, such as systems that minimize dust and overspray.

Materials and Advantages

Constructed to support sustainability, flat coating machines utilize materials that are environmentally conscious without compromising on performance. They offer advantages like uniform color application, excellent adhesion, and the ability to produce fade-resistant workpieces. Additionally, certain models offer high powder recovery rates, enhancing cost-effectiveness and material efficiency.

Technical Specifications

The technical prowess of these machines is reflected in their auto trimming systems and adjustable settings, which can range from 600 to 1300, catering to specialized coating needs. This adaptability ensures that a flat coating machine can be fine-tuned to deliver optimal results across various substrates and coating materials.

Environmental Impact and Efficiency

In an era where environmental impact is paramount, flat coating machines stand out for their eco-friendly operation. They are engineered to reduce waste and enhance efficiency, making them a responsible choice for businesses looking to minimize their ecological footprint while maintaining high standards of production.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4