Understanding Fast Wire Foam Cutters

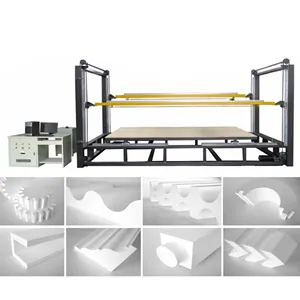

A fast wire foam cutter is a specialized industrial device engineered for slicing through foam materials with efficiency and precision. This equipment is pivotal in various industries, catering to the need for cutting foam into smaller, usable pieces. The versatility of these machines allows for a range of applications, from simple cuts for insulation materials to intricate shapes for artistic purposes.

Types and Applications

The spectrum of foam cutting machines includes basic models that utilize sharp blades for straightforward tasks, to more advanced CNC foam cutters that incorporate laser or hot wire technology. The simpler machines are adept at handling tasks where precision is less critical, such as cutting cushion fillers or insulation. In contrast, CNC variants are indispensable for complex and heavy-duty foam cutting projects, offering the capability to program specific shapes and designs remotely.

Features and Technology

Advanced CNC foam cutting machines stand out with their ability to execute precise cuts, employing either hot wire or laser technology. Hot wire cutters are noted for their efficiency in batch processing, while laser cutters are lauded for their precision, minimizing scorch marks on the foam. These machines are adaptable, capable of cutting various foam types, including XPS, EPE, and EPS, making them suitable for a broad range of projects.

Materials and Advantages

The construction of foam cutters is designed to handle the unique demands of cutting through foam-based materials. The advantages of using a fast wire foam cutter are manifold, including the ability to produce clean cuts, maintain consistency in production, and save time with automated processes. This makes them an invaluable asset in sectors such as furniture design, 3D printing, and home decorating.

Choosing the Right Machine

Selecting the appropriate foam cutting machine is crucial for meeting the specific needs of a project. For industrial-scale operations, robust CNC machines are ideal, while for smaller-scale or home-based projects, electric foam cutters that connect to mains electricity might suffice. These smaller devices often feature a heated element for cutting, offering convenience and ease of use.

Conclusion

Whether for industrial use or smaller creative endeavors, a fast wire foam cutter is a tool that offers versatility and precision. While Alibaba.com serves as a platform to connect buyers with a wide array of suppliers, it is essential to assess the specific requirements of your project to find the most suitable foam cutting solution.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4