Understanding Electrical Metallic Tubing (EMT)

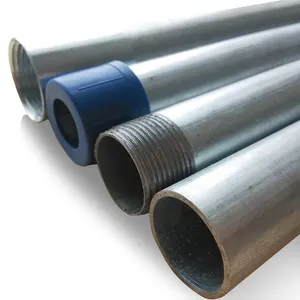

Electrical Metallic Tubing (EMT), a vital component in modern electrical infrastructure, serves as a crucial safeguard for electrical wires. This tubing, crafted primarily from galvanized steel, zinc, and carbon steel, is engineered to protect and route electrical wiring within a variety of structures.

Types and Applications of EMT

The versatility of EMT electrical conduit is reflected in its wide range of types and applications. From emt conduit electrical systems in commercial buildings to emt electrical tubing in industrial settings, these conduits are designed to ensure the safe and efficient management of electrical wiring. The metallic tube variants are particularly suited for environments where durability and protection against physical damage are paramount.

Features and Materials

EMT pipe is distinguished by its features that cater to different environmental needs. The materials used, such as anti-corrosion coated steel, ensure longevity and reliability. The tubing's construction allows for it to be lightweight yet durable, making it a preferred choice for a myriad of installations.

Advantages of Using EMT

The use of electrical metallic tubing offers numerous advantages. Its ease of installation and maintenance makes it a cost-effective solution for protecting electrical wires. The tubing's resistance to impact and moisture contributes to enhanced safety and longevity of the electrical systems it houses.

Complementary Solutions

In addition to EMT, other solutions like imc electrical pipe, rigid metal conduit, and conduit flexible pipe are available to meet diverse installation needs. For scenarios demanding flexibility, flexible pipe for electrical wiring provides an adaptable option, complementing the more rigid structure of emt conduit pipes.

Choosing the Right EMT

Selecting the appropriate electrical metal conduit involves considering factors such as environmental conditions, the type of electrical system, and specific regulatory requirements. While electrical nonmetallic tubing might be suitable for certain conditions, the robust nature of metal electrical tubing often makes it the go-to choice for many commercial and industrial applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4