Understanding Cyclone Technology

Cyclone technology is a critical component in various industrial processes, particularly in the realms of water treatment, filtration, and purification. A cyclone separator is an equipment designed to remove particulates from air, gas, or liquid stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids, making it a versatile and essential tool in numerous sectors.

Types and Applications of Cyclone Equipment

There are several types of cyclone equipment, each suited to specific applications. The most common include the single-cyclone, multi-cyclone, and the hydrocyclone. Each type serves a unique purpose, from removing pollutants from the air to separating sand and silt from water in wastewater treatment facilities. The application of cyclone technology spans across industries such as mining, agriculture, and pharmaceuticals, showcasing its wide-ranging utility.

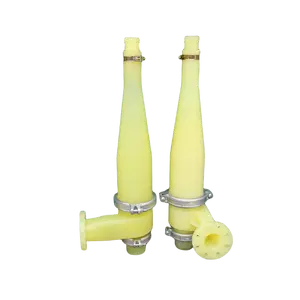

Features and Materials of Cyclone Devices

Cyclone devices are known for their robust construction and efficiency. They are typically made from materials like stainless steel, ceramic, or other metals that offer durability and longevity. The design of a cyclone collector includes components such as a cylindrical top section, conical base, and a dust outlet. These features work together to facilitate the swift separation of materials, ensuring a seamless operation.

Selecting the Right Cyclone Separator

When selecting a cyclone separator, it is crucial to consider the specific needs of your operation. Factors such as the particulate size, density, and the volume of air or liquid to be treated are paramount. Additionally, the operational environment and the physical space available for the installation of the cyclone also play a significant role in the selection process. Understanding the limitations and capabilities of different cyclone models is essential for optimal performance.

Advantages of Cyclone Systems

Cyclone systems offer several advantages. They are highly effective at particulate removal, have low maintenance requirements, and are relatively easy to install. Moreover, the efficiency of a cyclone dust collector is not affected by humidity levels, making it a reliable option in various climatic conditions. The simplicity of the cyclone design translates to fewer moving parts, which reduces the risk of mechanical failure.

Operational Considerations for Cyclone Units

Operational considerations for a cyclone unit include understanding the maximum load capacity and the appropriate lifting distance. Overloading a cyclone can result in malfunctions, while the lifting distance will determine if the unit is suitable for short or long-range material movement. The source of power, whether hydraulic, pneumatic, electric, or manual, will influence the cyclone's speed and precision, thus affecting the overall efficiency of the process.

![[Handy-Age]-1.5 HP Moveable Canister Cyclone (MW1700-014)](https://s.alicdn.com/@sc04/kf/UTB8out5k9bIXKJkSaefq6yasXXan.jpg_300x300.jpg)

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4