Exploring the Versatility of Curved Magnets

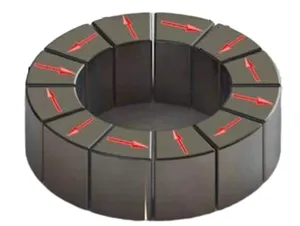

Curved magnets, a specialized segment within the magnet industry, cater to a unique set of applications where standard straight magnets fall short. These magnets, often incorporating neodymium, iron, and boron, are crafted to fit specific curvature requirements, enabling them to adhere to non-flat surfaces with ease.

Types and Applications of Curved Neodymium Magnets

The curved neodymium magnets are designed to serve a diverse array of applications. Their unique shape makes them suitable for integration into electrical equipment where the magnetic field needs to conform to a curved surface. These neodymium curved magnets are commonly found in advanced technological applications, ranging from automotive components to specialized industrial machinery.

Features and Material Composition

The material composition of curved neodymium magnet products ensures durability and a strong magnetic field. Neodymium, a key component, is known for its strong magnetic properties, which are enhanced by the addition of iron and boron. The structural integrity of these magnets is fortified by these materials, providing a robust solution for various applications.

Advantages of Neodymium Magnets Curved

The neodymium magnets curved configuration offers several advantages. Their permanent magnetic property ensures longevity and sustainability, minimizing the need for replacement. The adaptability of these magnets is evident in their ability to be customized in size and shape, catering to specific industry needs. Furthermore, their compatibility with a range of materials like metal, plastics, and rubber, extends their usability across different sectors.

Customization and Sustainability

Customization is a key feature of curved magnets, with suppliers offering various options to match precise requirements. These magnets are not only tailored in terms of shape and size but also come with different coating options, such as black epoxy, to enhance their durability and performance. The sustainable aspect of these magnets is reflected in their permanent nature, reducing waste and the need for frequent replacements.

Quality and Certification

Quality assurance is paramount for these specialized magnets. Suppliers ensure that the curved neodymium magnets meet rigorous standards, with certifications like ISO, REACH, and ROHS. These certifications attest to the magnets' compliance with international standards, ensuring that they are suitable for a wide range of commercial and industrial uses.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4