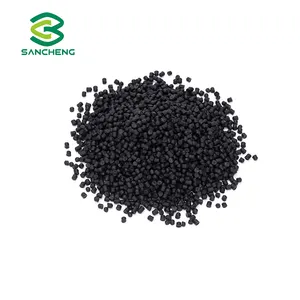

Introduction to CPVC Granules for Fitting

Chlorinated Polyvinyl Chloride, commonly known as CPVC, is a versatile material used extensively in the production of fittings and fixtures in various industries. CPVC granules for fitting are the primary form of this thermoplastic, tailored for molding into a wide array of shapes and sizes to meet the diverse needs of plumbing systems and other applications requiring high-temperature resistance and durability.

Characteristics of CPVC Fittings

CPVC fittings are known for their thermal stability, chemical resistance, and flame retardancy, making them suitable for hot and cold water distribution. The granules are designed to withstand corrosive water at higher temperatures than their PVC counterparts. This inherent resilience of CPVC granules ensures longevity and reliability in the systems they are integrated into.

Applications of CPVC Granules

The application of CPVC granules extends beyond plumbing to include industrial liquid handling and fire suppression systems. Due to their high-temperature tolerance, CPVC granules for fitting are also utilized in the manufacturing of specialty components in the chemical processing industry. Their adaptability allows them to be a material of choice for various end-use scenarios.

Manufacturing and Molding

The granular form of CPVC is particularly advantageous for manufacturers, providing ease of transport and handling before the molding process. These granules are conducive to precise measurements and mixtures, ensuring consistency in the production of CPVC fittings. The molding process transforms these granules into durable, robust fittings that maintain their structural integrity under stress.

Environmental Impact and Sustainability

CPVC recycling is an important aspect of the material's life cycle. The thermoplastic nature of CPVC allows for it to be reprocessed without significant degradation of its properties. This promotes a sustainable approach to material usage, where CPVC waste can be converted back into usable granules, contributing to the circular economy within the plastics industry.

Choosing the Right CPVC Granules

Selecting the appropriate grade of CPVC granules for fitting is crucial for manufacturers. Factors such as flow rate, thermal stability, and material compatibility are essential considerations. The granules come in various grades, each suited to specific conditions and applications, ensuring that the final product meets the required performance standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4