Understanding Spinning Machines for Cotton Fiber

Spinning machines for cotton fiber are specialized equipment tailored for converting cotton fibers into yarn, playing a vital role in the textile industry. They form the foundation for producing various cotton-based products, including apparel and home textiles. The core function of these machines is to extract fibers from raw cotton and twist them into a continuous thread structure, which can then be further processed or woven into fabric.

Common users of spinning machines are textile mills, garment manufacturers, and industries requiring a consistent supply of high-quality cotton yarn. Technological advancements, such as digital controls, automation, and precision engineering, have enhanced the efficiency and efficacy of spinning machines to meet the escalating demands of textile production.

The operation of spinning machines comprises multiple stages meticulously coordinated to ensure the final product meets specific criteria. Initially, raw cotton fibers are cleaned and carded to align them, followed by drawing them into a fine strand and twisting them to enhance strength and durability. The resultant yarn may undergo additional treatments with chemicals or oils based on intended applications like dyeing or enhancing performance attributes.

Diverse Types of Spinning Machines for Cotton Fiber

The textile machinery sector offers various types of machines, each serving distinct functions in the cotton spinning process. Here's an overview of the key types:

-

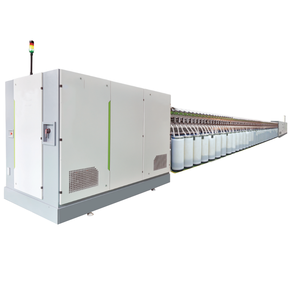

Rotor Spinning Machine: Known for its productivity and cost efficiency, this type operates by rotating a cylindrical rotor to draw fibers outward, creating yarn with low twist but good strength. It is commonly used for producing medium to coarse yarn suitable for weaving or knitting.

-

Ring Spinning Machine: Among the oldest and most versatile methods, ring spinning involves pulling cotton fibers through a small ring, resulting in softer and more uniform yarn compared to rotor spinning, ideal for fine fabrics.

-

Open-End Spinning Machine: This type spins yarn from a continuous fiber supply with less twist, making it suitable for bulkier products like blankets, rugs, and denim fabrics.

Each spinning machine type offers unique features catering to diverse requirements such as material selection, yarn characteristics, and production scale, from small-scale enterprises to large commercial operations.

Factors to Consider When Selecting a Spinning Machine for Cotton Fiber

Choosing the appropriate spinning machine for your business necessitates thoughtful evaluation of several factors:

-

Machine Type: Select a machine aligning with your operational needs; for instance, a ring spinning machine may be preferable for flexibility in producing various yarn types regularly.

-

Production Volume: Ensure the machine's capacity matches your expected output; high-volume operations may benefit from efficient machines with large spindle capacities.

-

Productivity Features: Look for machines offering operational ease, high productivity, low maintenance, and robust after-sales support, as these features can significantly impact business performance.

-

Technical Support: Access to prompt technical assistance is crucial; suppliers should provide adequate support for installation, operation, and maintenance.

-

Quality Assurance: Opt for a machine with a proven track record of consistent quality to ensure the end product's quality aligns with your expectations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4