Popular in your industry

Related Searches:

Top categories

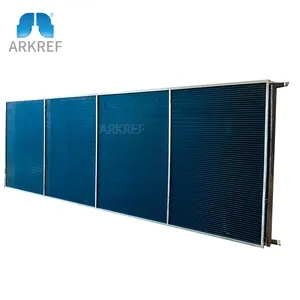

About copper coil heat exchanger

Copper Coil Heat Exchanger: An Overview

The copper coil heat exchanger stands as a pivotal component in various industrial and residential systems, where temperature regulation of fluids is crucial. Its primary function is to transfer heat between two or more fluids, making it an indispensable part of systems that require heating or cooling to operate efficiently.

Types and Applications

There are several types of copper coil exchangers, each serving specific applications. The spiral copper tube heat exchanger, for instance, is designed for spaces where a compact solution is needed without compromising efficiency. These are often found in applications ranging from power generation to residential heating systems. On the other hand, the copper tube coil immersion heat exchanger is typically used in applications requiring direct contact with the fluid being heated, such as in tanks or large containers.

Features and Materials

Copper, known for its excellent thermal conductivity, is the material of choice for these heat exchangers. The copper heat coil is not only efficient in transferring heat but also exhibits corrosion resistance and antimicrobial properties, making it suitable for systems involving potable water. The durability of copper also lends itself well to the diy copper coil heat exchanger market, where longevity and reliability are key considerations.

Advantages of Copper Coil Tubing in Heat Exchangers

The use of copper coil tubing heat exchanger designs brings several advantages. Their high thermal conductivity ensures rapid heat transfer, which is essential in industrial processes where temperature control is critical. Moreover, the inherent strength of copper allows these exchangers to withstand high-pressure environments, making them ideal for rigorous applications.

Selection Considerations

When selecting a copper water heating coil, it is important to consider the specific requirements of the application. Factors such as fluid compatibility, temperature ranges, and pressure ratings are critical to ensure optimal performance and longevity of the heat exchanger. It is also essential to consider the design, with options like shell and tube or plate heat exchangers available to match different operational demands.

Conclusion

In conclusion, the copper coil heat exchanger category encompasses a range of products tailored for diverse applications. From industrial to residential settings, these exchangers play a key role in efficient thermal management. Prospective buyers are encouraged to assess their specific needs to find the most suitable copper coil heat exchanger variant, ensuring a balance between performance and durability.