Popular in your industry

Related Searches:

Top categories

About conveyor roller

Introduction to Conveyor Rollers

Conveyor rollers are integral components of material handling systems, designed to facilitate the transportation of goods across various industrial sectors. These rollers support and move conveyor belts or other conveying systems, enabling efficient and consistent movement of products within a facility.

Types and Applications of Conveyor Rollers

Roller conveyor systems are versatile and come in various types, such as gravity roller conveyors and powered roller conveyors. Gravity rollers rely on inclination or manual force, while powered rollers use motorized means to move goods. These systems are crucial in manufacturing, packaging, and distribution operations, accommodating a range of products from lightweight packages to heavy pallets.

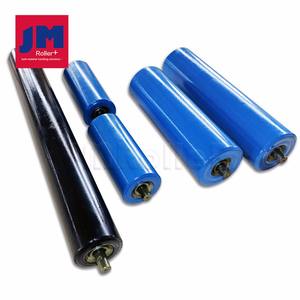

Features and Materials

The construction of conveyor belt rollers involves materials like steel, plastic, and rubber, each selected for durability and suitability to the application's environment. Idler rollers and driven rollers are designed to withstand various loads, with some featuring reinforced steel rings for added strength. The choice of material impacts the roller's longevity and performance in different industrial settings.

Advantages of Roller Conveying Systems

Roller conveying systems offer numerous advantages, including improved facility safety, reduced labor costs, and enhanced process efficiency. The simplicity of gravity conveyor systems makes them a cost-effective solution for many logistical challenges, while powered roller conveyor systems provide greater control and can handle higher volumes and weights.

Roller Types and Specifications

There is a diverse range of roller types available, each tailored for specific applications. For instance, conveyor belt drive rollers are designed to propel belts with precision, whereas gravity rollers are ideal for facilitating a natural flow of goods. Specifications such as diameter, load capacity, and material composition are carefully considered to meet the demands of various operations.

Complementary Components

In addition to rollers, a comprehensive roller conveyor system includes various complementary components like conveyor belt and rollers, rollers and idlers, and roller drums. These parts work in unison to ensure the smooth operation of the conveying system, contributing to the overall productivity of the material handling process.