Introduction to Conveyor Belts for Sand Washing

Conveyor belts designed for sand washing are integral components in the material handling sector, streamlining the transportation and cleaning of sand in various industrial settings. These specialized belts are engineered to facilitate the movement and processing of sand, enhancing efficiency and productivity in operations such as mining, construction, and aggregate production.

Types and Applications

The versatility of conveyor belts for sand washing is evident in their various types, each suited to specific industrial needs. Flat belt conveyors are commonly used for their simplicity and suitability for moving materials over level distances, while cleated belt conveyors are preferred when there is a need to transport materials at an incline. These conveyors are not only pivotal in sand washing but also in the broader scope of material handling, including the movement of aggregates and minerals.

Operational Features

A conveyor belt for sand washing is characterized by features that promote operational control and adaptability. With the ability to handle different material sizes and weights, these conveyors can be adjusted to suit the specific requirements of a sand washing operation. The incorporation of advanced controls allows for precise management of the sand movement, contributing to a more streamlined process.

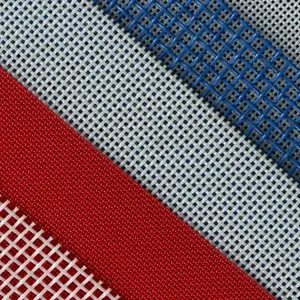

Material and Construction

The construction materials of a conveyor belt for sand washing are selected for durability and suitability to the task. Typically, these belts are made from robust materials that can withstand the abrasive nature of sand and the rigors of the washing process. The choice of material also considers the environmental conditions of the workplace, ensuring longevity and consistent performance.

Advantages of Using Conveyor Belts in Sand Washing

Employing a conveyor belt for sand washing brings several advantages, such as reducing the risk of material loss and damage. By automating the movement of sand, these belts minimize the need for manual handling, thereby reducing the risk of workplace injuries and allowing for a more efficient allocation of human resources. Additionally, the precision offered by these systems can lead to a reduction in operational downtime.

Considerations for Selection

When selecting a conveyor belt for sand washing, it is crucial to consider factors such as the specific needs of the operation, the environmental conditions, and spatial constraints. The chosen conveyor should align with the operational goals, be capable of withstanding the workplace's environmental conditions, and fit within the designated space while accommodating the volume and nature of the materials to be processed.

For those in the market for a conveyor belt for sand washing, Alibaba.com offers a diverse array of options through its partnerships with various suppliers. The platform's search feature enables buyers to find a conveyor system that aligns with their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4