Introduction to Continuous Foaming Machines

Continuous foaming machines are integral to various industries, serving a pivotal role in the production of foam materials. These machines are designed for the consistent manufacturing of foam, which is essential in packaging, insulation, and various other applications. The continuous foam production process ensures a steady supply of material, meeting the demands of large-scale operations.

Types and Applications

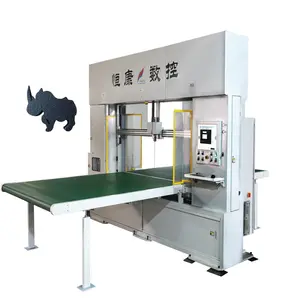

There are several types of continuous foaming machines, each tailored to specific production needs. These range from block foaming machines to specialized machinery for creating intricate foam shapes. The applications are diverse, encompassing the use in the manufacturing sector for cushioning and protective packaging, in the pharmaceutical industry for safe transport of sensitive products, and in the electrical industry as insulation due to foam's low thermal conductivity.

Features and Materials

The materials used in continuous foam production machines are chosen for their durability and performance. The machinery often incorporates advanced control systems for precise operation, ensuring the foam produced meets strict quality standards. The foam itself is characterized by its excellent shock absorption capabilities, capable of supporting many times its own weight, which is why it is favored for protective packaging solutions.

Advantages of Continuous Foaming

The advantages of using a continuous foaming machine are manifold. The foam's structure, with its molecular cells forming air chambers, provides exceptional insulation properties. This is particularly beneficial for the transportation of perishable goods, as it helps maintain a controlled environment, reducing the risk of bacterial and fungal growth without altering the taste or scent of the packaged items.

Environmental and Safety Considerations

Safety and environmental considerations are paramount in the design of continuous foaming machines. The foam produced is treated to minimize electrostatic energy, reducing the risk of damage to sensitive products. Furthermore, the non-toxic nature of the foam ensures that it does not react with the contents it secures, making it a safe choice for food preservation and transport.

Choosing the Right Machine

Selecting the appropriate continuous foaming machine price point involves considering the specific requirements of your production line. Alibaba.com lists a variety of machines, allowing businesses to find the right fit for their operational needs without compromising on efficiency. While exploring the extensive inventory, buyers can connect with suppliers to ensure that their selected machinery aligns with their production goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4