Understanding the Condenser Tube Cleaning System

A condenser tube cleaning system is an integral component in maintaining the efficiency of various heat exchange equipment. This system is designed to remove fouling and scale buildup from the inner walls of the condenser tubes, which are crucial for the optimal performance of chillers, heat exchangers, and other industrial cooling apparatus.

Types and Applications

The applications of a condenser tube cleaning system are diverse, ranging from large-scale industrial cooling to HVAC systems in commercial buildings. Among the types available, the automatic tube cleaning system and the automatic condenser tube cleaning system stand out for their efficiency in continuous cleaning without manual intervention. The auto tube cleaning system for chillers is specifically designed to maintain chiller efficiency by preventing the accumulation of debris on the tube surfaces.

Features and Materials

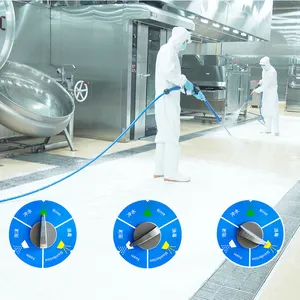

Key features of these systems include the automatic tube brushing system for chillers, which employs mechanical brushes to scrub the interior surfaces of the tubes. Additionally, the ball cleaning system condenser utilizes specially designed condenser cleaning balls that are circulated through the tubes to dislodge and remove scaling and fouling. Materials used in these systems are selected for their durability and compatibility with the cooling system's operating environment, ensuring longevity and reliability.

Advantages of Automated Cleaning

The adoption of an automatic condenser cleaning system offers numerous advantages. It significantly reduces downtime by cleaning during operation, known as an online tube cleaning system. This not only enhances the heat transfer efficiency but also extends the lifespan of the equipment. Moreover, the condenser online tube cleaning system minimizes the need for chemical cleaning, thus reducing environmental impact and operational costs.

Selection and Integration

Choosing the right condenser tube cleaning system involves considering the specific requirements of the chiller or heat exchanger. Factors such as tube material, diameter, and the nature of the fouling must be taken into account. While Alibaba.com does not directly provide these systems, the platform offers a vast selection from various suppliers, enabling businesses to find a system that aligns with their needs.

Conclusion

In conclusion, a condenser tube cleaning system is essential for the maintenance and efficiency of heat exchange equipment. With the availability of advanced systems like the automatic tube cleaning and chiller condenser cleaning technologies, businesses can ensure their operations remain uninterrupted and cost-effective. Alibaba.com serves as a marketplace to connect with a multitude of suppliers offering these innovative solutions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4