Understanding Compression Molding

Compression molding is a versatile and efficient method of molding that has been adopted across various industries. This process involves placing a plastic material into a heated mold, and then applying pressure to shape it into the desired form. The technique is particularly beneficial for creating large, intricate designs and is a cornerstone in the manufacturing of a wide range of compression molding products.

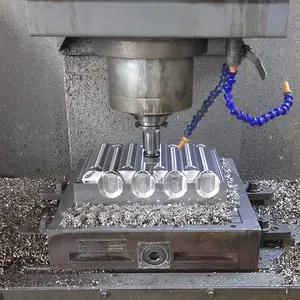

The Compression Molding Process

The compression molding process begins with a preheated polymer placed into an open, heated mold cavity. The mold is then closed with a top plug and pressure is applied, allowing the material to 'flow' and fill the shape of the mold. Press molding process, a related technique, also involves applying pressure to the material but differs slightly in methodology and application.

Materials and Applications

Plastic compression molding and rubber compression molding are two primary applications of this technique. Plastics are used for their versatility and durability, while rubber molding is preferred for its elasticity and resilience. Silicone compression molding is also popular due to silicone's heat resistance and flexibility. These materials are used in automotive parts, electronics, and household goods, showcasing the method's broad applicability.

Features and Advantages of Compression Molding

One of the significant advantages of compression molding is its ability to produce large and complex parts. Composite compression molding is particularly known for creating parts with superior strength and lightweight characteristics, such as carbon fiber components. The compression molding method is also cost-effective for high-volume production, as it allows for quick cycle times and the use of regrind.

Specialized Compression Molding Techniques

Advancements in the field have led to specialized techniques like injection compression molding and prepreg compression molding. Injection compression molding combines the benefits of both injection and compression molding, suitable for creating parts with tight tolerances and high-quality surfaces. Prepreg compression molding, on the other hand, uses pre-impregnated fibers, often in composite compression moulding, to achieve superior strength-to-weight ratios in components.

Selecting the Right Compression Molding Service

When exploring the options for compression molding services, it is crucial to consider the expertise of the processors. Factors such as the type of compression molding press used, the materials they specialize in, and their capacity to produce test samples to ensure mold accuracy are essential. Alibaba.com facilitates the connection between businesses and experienced suppliers, offering a platform to find the right service for your compression molding needs without the hassle.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4