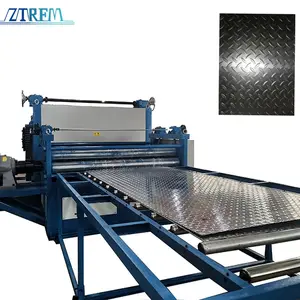

Introduction to Cold Rolling Embossing Machines

Cold rolling embossing machines are specialized equipment used in the metalworking industry to create intricate patterns and designs on metal surfaces. These machines leverage the cold rolling process, which involves the deformation of metal at room temperature to alter its shape and surface texture without compromising its structural integrity. The versatility of cold rolling steel embossing machines makes them an essential tool for various applications, including decorative paneling, automotive parts, and architectural elements.

Types and Applications

There are several types of cold rolling embossing machines, each designed to meet specific industry needs. Some machines are equipped with a vertical movement mechanism, ideal for stamping and bearing work, while others feature a lateral motion for broader applications. These machines are not limited to metalworking; they can also handle other materials, making them suitable for a wide range of applications from textile to polymer embossing.

Operational Features

The operational features of a cold rolling embossing machine include adjustable pressure settings, which allow operators to tailor the force applied to the workpiece. This semi-automatic machinery requires manual adjustment to ensure precision in the embossing process. Additionally, the heat plates, typically made from aluminum, are coated with non-stick materials to ensure even heat distribution and prevent material adherence during operation.

Machine Construction and Materials

The construction of a cold rolling steel embossing machine is robust, with heat plates and accessory components designed for durability and performance. The non-stick coating on the aluminum plates is a critical feature, aiding in the maintenance of the machine and the quality of the embossed products. Underneath the heat plates, heat-resistant rubber pads provide a safe and stable base for various materials.

Advantages of Using Cold Rolling Embossing Machines

The use of cold rolling embossing machines offers numerous advantages, such as the ability to produce consistent, high-quality patterns with fine detail. The strength and durability of the machines ensure they can withstand the demands of continuous industrial use. Moreover, the flexibility in design and operation allows for customization, catering to a broad spectrum of embossing requirements.

Choosing the Right Machine on Alibaba.com

Alibaba.com presents a diverse selection of cold rolling embossing machines to meet the needs of global wholesalers and businesses. Whether the task involves printing on textiles or creating patterns on non-flat items, the platform connects buyers with a variety of machines to suit different scales of operation, from portable units for small-scale projects to larger machines for industrial production.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4