Exploring the Versatility of Cold Rolled Steel Angle Iron

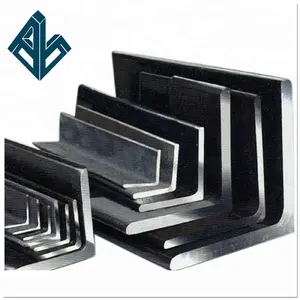

Cold rolled steel angle iron is a pivotal component in modern construction and industrial applications. Its L-shaped cross-section provides a unique combination of strength and rigidity, making it a preferred choice for structural support and reinforcement. This introduction delves into the nuances of cold rolled angle iron, emphasizing its manufacturing processes, dimensions, and applications.

Manufacturing Techniques and Material Composition

The production of cold rolled steel angle iron involves various techniques to enhance its structural integrity. Unlike hot rolled steel, the cold rolling process increases the yield strength and surface finish of the steel, resulting in a more precise angle size and improved straightness. The cold formed steel angle sizes range from the compact 25mm x 25mm to the more substantial 250mm x 250mm, catering to diverse structural requirements. The material composition includes stainless steel, carbon steel, and galvanized steel, each selected for its specific properties, such as corrosion resistance and tensile strength.

Design Features and Applications

The design of cold rolled steel angle iron is tailored to meet the demands of various applications. From the construction of transmission towers and shelving to roof construction and structural reinforcement, the versatility of this material is unmatched. The cold rolled angle iron is available in both perforated and non-perforated variants, with the former allowing for bolted connections and the latter suitable for welding. Additionally, the unequal angle steel provides an asymmetric profile for specialized construction needs.

Dimensions and Standards

Adhering to international standards, cold rolled steel angle iron is produced in lengths typically ranging from 6m to 12m, with thicknesses starting at 2.5mm and extending up to 35mm. The diversity in dimensions ensures that cold formed steel angle sizes are compatible with various design specifications and construction practices globally. This adaptability makes it a reliable choice for both domestic and international projects.

Structural Integrity and Support

The structural benefits of cold rolled steel angle iron are evident in its use for supporting brickwork and motor in building construction. The double ribbed design, in particular, offers enhanced support for doors and windows, ensuring stability and longevity. The cold formed steel angle's resistance to bending under stress is a testament to its role in creating safe and durable structures.

Conclusion

For those in search of a robust and versatile building material, the cold rolled steel angle iron presents itself as an indispensable option. Its array of sizes, finishes, and material compositions makes it suitable for a wide range of applications. While exploring the offerings on Alibaba.com, buyers can find a comprehensive selection of cold rolled steel angle options to meet their specific project requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4