Introduction to Coil Rolling Machines

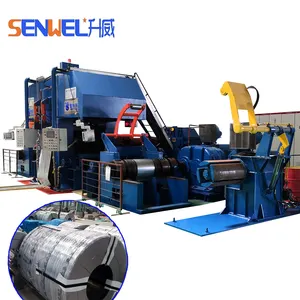

Within the manufacturing sector, the coil rolling machine stands as a pivotal equipment, designed to enhance the efficiency of metalworking processes. These machines are engineered to transform metal strips into coils through a series of rolls, ensuring a high level of precision and consistency in production.

Types and Applications

The versatility of coil rolling machines is evident in their various types, each tailored to specific industry requirements. From sheet metal rollers to heavy-duty coil applications, these machines cater to a broad spectrum of metalworking tasks. Their applications are equally diverse, serving industries ranging from automotive to construction, where the fabrication of metal components is essential.

Operational Features

One of the standout features of a coil rolling machine is its automated control system, which ensures accurate and consistent rolling. The precision-engineered components of these machines contribute to their ability to produce uniform products with minimal waste. Furthermore, the ease of operation allows for a smoother workflow, as specialized skills are not a prerequisite for handling these machines.

Material Considerations

When selecting a metal rolling machine, the material specifications are paramount. Machines vary in their capacity to handle different metal types, gauges, and widths. It is crucial to choose a machine that aligns with the material properties you intend to work with, ensuring the longevity and efficiency of the equipment.

Advantages of Modern Coil Rollers

The modern plate bending roll machines offer significant advantages in terms of production speed and cost-effectiveness. By expediting the manufacturing process, these machines contribute to a faster return on investment. Additionally, the high degree of automation reduces the likelihood of errors, thereby decreasing material wastage and ensuring product uniformity.

Choosing the Right Machine

When in the market for a steel rolling machine, durability is a critical factor. Machines constructed with robust materials like steel are preferred for their strength and longevity, ensuring they can withstand the rigors of continuous operation. It is essential to assess the machine's specifications to ensure it meets the demands of your production requirements.

For those seeking a comprehensive selection of coil rolling machines, Alibaba.com offers a platform where a variety of models are available to meet diverse operational needs. The site provides a convenient and efficient way to connect with suppliers, facilitating the procurement of machines that align with your business objectives.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4