Popular in your industry

Related Searches:

Top categories

About co2 welding tips

Introduction to CO2 Welding Tips

CO2 welding tips are integral components in the metal fabrication process, specifically designed for MIG (Metal Inert Gas) welding applications. These tips are crucial for directing the flow of CO2 gas and welding wire to the weld pool, ensuring a stable arc and quality welds. The precision in manufacturing CO2 welding tips contributes significantly to their performance and longevity in various welding tasks.

Types and Applications

The variety of CO2 welding tips caters to different welding requirements. From heavy-duty welding tips designed for industrial applications to precision welding tips for intricate work, the selection is diverse. Applications range from automotive repairs to construction and fabrication of metal structures. The adaptability of these tips to different welding environments makes them a staple in both professional and hobbyist toolkits.

Features and Materials

CO2 welding tips are characterized by their thermal conductivity and resistance to wear. Typically made from copper or copper alloys, these tips maintain their shape and electrical conductivity even under high temperatures. Advanced features include anti-spatter design and optimized gas flow, which enhance the welding process by reducing cleanup and ensuring a consistent gas shield around the arc.

Advantages of CO2 Welding Tips

The advantages of using CO2 welding tips are manifold. They provide improved arc stability and reduced spatter, which translates to less waste and higher efficiency. The durability of these tips means they require less frequent replacement, making them a cost-effective choice for continuous welding operations. Additionally, the compatibility of CO2 welding tips with various wire diameters allows for flexibility across different welding techniques and materials.

Selection Considerations

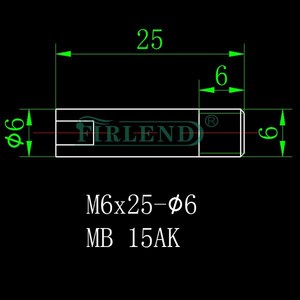

When selecting CO2 welding tips, it is important to consider the welding tip size and compatibility with the welding gun. The tip size must correspond to the wire diameter being used to ensure proper wire feeding and arc stability. Moreover, the choice of tip should align with the specific welding gun model to guarantee a secure fit and optimal performance.

Maintenance and Care

Proper maintenance of CO2 welding tips is essential for their performance and longevity. Regular cleaning to remove spatter and ensuring the correct alignment in the welding gun can prevent premature wear and welding defects. It is also advisable to inspect the tips for signs of damage or wear regularly and replace them as needed to maintain the quality of welds.