CNC Stone Carving Tools: An Overview

CNC stone carving tools are integral components in the realm of industrial milling, particularly for operations involving stone, granite, and marble. These precision instruments are designed for use with CNC (Computer Numerical Control) machinery, which has revolutionized the way stone is carved and shaped. Unlike standard milling bits that are limited to axial movements, CNC stone carving tools can maneuver in both axial and radial directions, enhancing their versatility in various applications.

Types and Applications

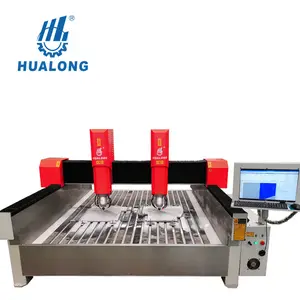

The utility of CNC stone carving tools extends across different axes of machinery. Three-axis CNC machines offer a foundational level of control, allowing the milling table to move in multiple directions, while four-axis units introduce a turnaround table, expanding their use in complex industries like automotive and aviation. The pinnacle of precision comes with the five-axis machines, which include three linear and two rotary axes, adjustable per model, making them suitable for intricate designs and patterns in stone CNC engraving machine applications.

Features and Materials

CNC stone carving tools are crafted from robust materials capable of withstanding the rigors of stone milling. The geometry of these tools varies, with options ranging from cylindrical to conical, and even complex shapes like hemispherical, to suit the diverse needs of stone carving CNC machine operations. These tools are not only used for the engraving and carving of stone but are also employed in the creation of detailed work on granite cutting CNC machines and marble carving machines.

Advantages of CNC Stone Carving

The advantages of using CNC stone carving tools are manifold. They enable the processing, cutting, and shaping of mechanical parts, either as unique pieces or in series production. The precision that a CNC jade carving machine or a CNC router stone engraving machine offers is unparalleled, allowing for the creation of complex designs that would be difficult, if not impossible, to achieve manually. Additionally, the adaptability of these tools across different CNC machine axes enhances their utility in a wide range of stone carving and engraving tasks.

Choosing the Right CNC Stone Carving Tool

Selecting the appropriate CNC stone carving tool requires an understanding of the specific project needs and the capabilities of the CNC machinery in use. Factors such as the type of stone, the intricacy of the design, and the desired finish all play a role in determining the right tool. Whether it's for a CNC stone engraving bits selection or a comprehensive CNC stone engraving tools kit, the choice must align with the task at hand to ensure optimal results.

Conclusion

In summary, CNC stone carving tools are essential for anyone involved in the industrial milling of stone and similar materials. Their ability to carve with precision and versatility makes them a valuable asset in a variety of professional settings. While the market offers a range of tools tailored to different aspects of stone carving and engraving, it is crucial to select the right tool for the job to achieve the desired outcomes in stone processing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4