Understanding Chipped Foam and Its Applications

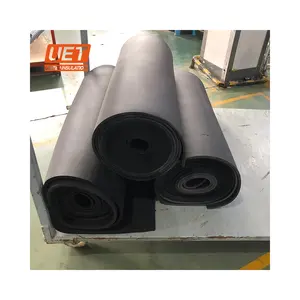

Chipped foam, a versatile material derived from various foam types, is essential in numerous industries for its cushioning and padding properties. This category encompasses a range of products tailored for specific uses, from packaging to furniture stuffing. The foam chips are created through a process of breaking down larger foam pieces into smaller, usable fragments.

Types and Features of Chipped Foam

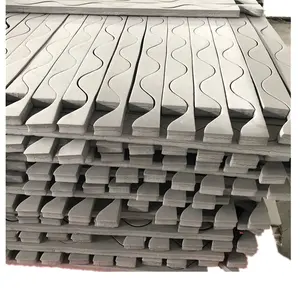

The diversity of chipped foam is evident in its various forms, such as memory foam chips, polyurethane foam chips, and ethylene-vinyl acetate (EVA) chips, each serving distinct functions. Memory foam chips, for instance, are known for their pressure-relieving qualities, while polyurethane foam chips are lauded for their resilience and affordability. EVA foam chips offer robustness and thermal insulation, making them suitable for a wide range of temperatures.

Chipped Foam in Industrial Use

In the industrial realm, chipped foam plays a critical role in the manufacturing and scrap business sectors, particularly in plastic product fabrication. It is utilized in foam filling and packaging solutions, providing protection and stability to goods during transportation. Moreover, chipped foam is integral in upholstery filling, contributing to the comfort and durability of furniture.

Environmental Impact and Recycling

The environmental aspect of chipped foam cannot be overstated. It is a prominent material in recycling efforts, often sourced from post-consumer goods to reduce waste. The use of chipped foam in eco-friendly practices underscores its role in promoting sustainability. By choosing recycled chipped foam, industries can significantly contribute to environmental conservation.

Technical Aspects and Machinery

The production of chipped foam involves sophisticated machinery designed to shred and repurpose foam efficiently. These machines are engineered to maintain energy efficiency and optimize output, ensuring that the foam chips meet industry standards. The technical process includes not only shredding but also pelletizing, where the foam is prepared for further use in various applications, such as pressure recycling and PET bottle flakes granulating.

Selecting Chipped Foam Products

When selecting chipped foam for business needs, it is crucial to consider the material's size, thickness, and durability to ensure it aligns with the intended application. Alibaba.com hosts a vast array of chipped foam options, allowing buyers to compare and choose based on their specific requirements without the influence of brand bias. The platform facilitates connections between buyers and reputable suppliers in the industry, offering a spectrum of chipped foam solutions.

![[XiBao]With Best Quality High Expanding Closed Cell Pu Spray Foam Polyurethane Foaming Agent](https://s.alicdn.com/@sc04/kf/H4b7b0bbfd50d43caa52bdaaa560c7432K.jpg_300x300.jpg)

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4