Introduction to Chili Tail Remover Machines

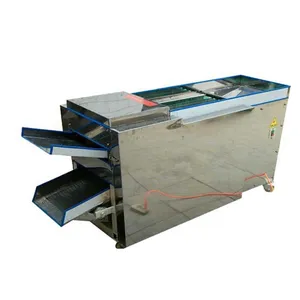

Chili tail remover machines stand as a testament to innovation in the agricultural processing industry. These machines are specifically designed to streamline the post-harvest process by efficiently removing the tails from chilies. This category of machinery is essential for businesses looking to enhance the presentation and quality of their chili products.

Design and Efficiency

The design of chili stem cutting machines incorporates advanced technologies that ensure precision and speed in the tail removal process. The construction of these machines from robust materials contributes to their durability and consistent performance. Their operational efficiency is a key factor in improving productivity for chili processors and packers.

Types and Applications

There is a diverse range of chili processing equipment available to suit various production demands. From compact models suitable for small-scale operations to industrial-grade machines for larger outputs, each is tailored to meet specific processing capacities. These machines are versatile, making them suitable for a variety of chili types, ensuring they are a valuable addition to food processing lines.

Features and Advantages

The automatic chili deseeding machine boasts features that promote ease of use and safety. They are engineered to conserve energy while maintaining high efficiency, which can contribute to lower operational costs. The advantages of using such machinery include not only increased production rates but also the uniformity of the final product, which is crucial for market appeal.

Materials and Sustainability

Manufacturers of chili cutting machines prioritize sustainability in their designs. The materials used are selected for their longevity and minimal environmental impact. This commitment to sustainability is reflected in the energy-efficient operation of the machines, which aligns with the growing demand for eco-friendly industrial practices.

Choosing the Right Machine

Selecting the appropriate chili tail cutter is pivotal for any business. Potential buyers are encouraged to consider their specific production needs and the various features offered by different models. While Alibaba.com does not endorse any particular brand or manufacturer, the platform facilitates the discovery of a wide array of machines to compare and choose from.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4