Defining High-Quality Ceramic Powder

Comprising fine particles derived from assorted ceramic materials, high-quality ceramic powders are indispensable in crafting ceramic goods. Industries such as aerospace, automotive, electronics, and construction utilize these powders for their exceptional material attributes and resistance to elevated temperatures. The production of these powders involves multiple stages, including the milling of raw materials to refine particle size and shape, and subsequent processing and sintering to fuse the particles.

The foremost advantage of superior ceramic powders lies in their capacity to preserve material integrity and functionality within the end product. This stems from the purity and uniformity of the particles, ensured by rigorous quality control protocols. High-quality powders also boast superior performance features, including robust chemical stability, mechanical strength, and thermal resistance, making them essential for applications where product dependability and longevity are critical.

Experts in sectors demanding precise material characteristics frequently employ these powders. In the medical realm, ceramic powders are instrumental in fabricating bio-inert implants that remain inert when in contact with bodily tissues. The electronics sector utilizes powders with specific electronic attributes to manufacture components for electronic devices. Thus, high-quality ceramic powders are fundamental to sophisticated manufacturing processes.

Varieties of High-Quality Ceramic Powder

A plethora of high-quality ceramic powders is available on the market, each tailored for specific uses. Below is a synopsis:

-

Alumina Ceramic Powder: Predominantly composed of aluminum oxide (Al2O3), this variant is celebrated for its formidable mechanical strength and resistance to abrasion. It is commonly employed in fabricating ceramic components that withstand wear and is a popular selection for industrial applications demanding high hardness.

-

Zirconia Ceramic Powder: Zirconia-based powders, often enhanced with yttria, are noted for their increased toughness and crack resistance. They are integral to sectors such as automotive, aerospace, and electronics, where reliability is of the essence.

-

Silicon Carbide Powder: Renowned for its extraordinary hardness and thermal conductivity, silicon carbide powder is utilized in cutting-edge refractories, abrasives, and high-tech electronics for its enduring nature.

-

Titania-based Powders: Incorporating titanium dioxide (TiO2), these powders are distinguished by their high whiteness and opacity. They play a crucial role in producing ceramic coatings where uniform color and finish are imperative.

-

Zirconium-based Powders: Offering a unique blend of toughness and corrosion resistance, zirconium-based powders are employed in nuclear reactors, chemical processing plants, and aerospace applications where high reliability is demanded.

Each type possesses distinct characteristics that render it apt for specific applications. For example, alumina ceramic powders are frequently used in creating wear parts for industrial machinery, while zirconia powders are chosen for their durability and wear resistance in electronics manufacturing.

Selecting High-Quality Ceramic Powder

When choosing high-quality ceramic powder for your enterprise on Alibaba.com, prioritize the intended application. For instance:

-

If your industrial manufacturing necessitates high-temperature stability, as in refractories or electronics, opt for materials like zirconia or alumina that provide exceptional thermal shock resistance.

-

For entities in the beauty or cosmetic industry seeking ingredients for their offerings, selecting the correct grade standard (such as industrial grade or reagent grade) is vital, considering regulatory compliance and product safety.

-

Choose coatings and pigments for product finishes based on desired attributes like hardness, color consistency, or chemical resistance.

-

In healthcare products like orthopedic implants or dental restorations, the choice of medical-grade ceramic powder that adheres to industry benchmarks is imperative.

Additionally, take into account processing capabilities such as molding or cutting if your application demands custom shapes or specific physical forms. Features like eco-friendliness or non-toxicity may also be significant for certain sectors, especially if the end products are intended for use in environments where safety is of utmost importance.

About High-Quality Ceramic Powder on Alibaba.com

Alibaba.com distinguishes itself as a leading online marketplace that bridges businesses worldwide with premier suppliers of ceramic powders. The platform showcases an expansive selection of powders apt for a variety of applications—from manufacturing plants to food-grade production—enabling businesses across diverse industries to find precisely what they require. With filters for application areas such as industrial settings or cosmetic production, buyers can effortlessly sift through options to locate powders that meet their specific needs.

The convenience Alibaba.com offers extends to product assortment and is complemented by features that facilitate smooth transactions. Mobile accessibility ensures that buyers can transact while on the move, while multilingual communication aids non-English speakers. Furthermore, Alibaba.com's Trade Assurance service provides an additional safeguard by securing payments until delivery confirmation.

By sourcing wholesale ceramic powders through Alibaba.com, businesses gain access to a global network of suppliers offering materials of high commercial value. Whether it's alumina ceram for specialized coatings or zirconia ceram for dental applications, purchasers can transact with confidence, knowing they are connected to a wide range of products and dependable services, all designed to streamline international trade efficiently.

Common FAQs for High-Quality Ceramic Powder

What are the primary applications of ceramic powder in industrial settings?

Ceramic powder is widely utilized in a host of industrial applications, from producing refractory materials for furnaces to crafting structural ceramics in aerospace and automotive sectors, among numerous others.

How do I determine the grade standard of a ceramic powder?

The grade standard of a ceramic powder denotes its quality classification, reflecting its purity, composition, and attributes such as particle size distribution. It is essential to choose a powder with a grade standard that aligns with your application's needs.

What factors should I consider when selecting a ceramic powder for my business?

Take into account the intended end-use, the requisite properties (e.g., thermal resistance, chemical composition), the performance grade (e.g., industrial, reagent), and the powder's adherence to industry norms.

Can I find eco-friendly ceramic powders for sustainable applications?

Indeed, eco-friendly options such as water purification-grade and food-grade ceramic powders are available, suitable for sustainable applications owing to their non-toxic characteristics.

Are there different colors of ceramic powder available for aesthetic purposes?

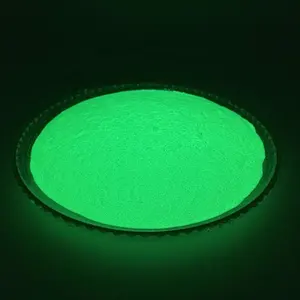

Ceramic powders are available in a spectrum of colors, including white, red, gray, black, light yellow, and others. The color selection may be influenced by the application's need for visual appeal or branding considerations.

What is the significance of the particle size distribution in ceramic powders?

The particle size distribution impacts the material's attributes, such as strength and uniformity. It is crucial to align the particle size distribution with your application's requirements to ensure peak performance.

How does purity level affect the performance of ceramic powder?

Higher purity levels in ceramic powders typically correlate with enhanced performance characteristics, such as greater insulation strength in refractory materials or improved clarity in optical-grade ceramics.

What are the advantages of using zirconium oxide powder in ceramic manufacturing?

Zirconium oxide powder is esteemed for its exceptional thermal shock resistance, chemical inertness, high-temperature strength, and low thermal conductivity, making it apt for a range of refractory and thermal insulation applications.

Is it possible to obtain samples of ceramic powder before making a bulk purchase?

Certain suppliers may provide samples of their ceramic powder, allowing businesses to assess the material's suitability for their specific application prior to a substantial purchase.

How does the classification system work for ceramic powders?

Ceramic powders are classified according to their intended use, such as industrial, reagent, food-grade, medical grade, etc. This system enables businesses to easily pinpoint the appropriate ceramic powder for their particular requirements.

Can I use ceramic powder for 3D printing applications?

Some ceramic powders are formulated for 3D printing applications. They must be finely graded and tailored to the specific demands of the printer to ensure quality and efficacy.

Are there any safety concerns when handling ceramic powder in an industrial environment?

Indeed, ceramic powders can pose health hazards if inhaled in powdered form. Adequate safety measures, including the use of personal protective equipment (PPE), proper ventilation, and adherence to material safety data sheet (MSDS) guidelines, are essential.

What does water treatment grade mean in the context of ceramic powders?

Water treatment grade denotes ceramic powders specifically produced for water purification, commonly used in water treatment systems to eliminate contaminants.

How do I determine the right amount of ceramic powder needed for my application?

The requisite amount of ceramic powder is contingent upon the specifications of the application. It is important to calculate the necessary volume of material and align this with the supplier's volume or weight specifications.

Can I request custom formulations for ceramic powders?

Many suppliers on Alibaba.com offer processing services such as molding or cutting to provide custom formulations that meet the specific needs of your application.

What is meant by apparent density in the context of ceramic powders?

Apparent density in ceramic powders refers to the volume the powder occupies post-compaction. This measure is significant for gauging the ease of flow and manageability of the powder in manufacturing processes.

Why might I choose an industrial-grade over a commercial-grade ceramic powder?

Industrial-grade ceramic powders are tailored for heavy-duty applications that demand high strength, thermal resistance, and durability, thus being well-suited for strenuous industrial conditions.

What does commercial use mean in relation to ceramic powders?

Commercial use pertains to ceramic powders that fulfill the requisite standards for commercial applications, such as in electronic components, wear-resistant coatings, and refractory materials.

Is it possible to obtain a sample of ceramic powder before placing a bulk order?

Many suppliers on Alibaba.com provide the option to procure samples of their ceramic powder, enabling businesses to test the product's compatibility before finalizing a larger order.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4