Top categories

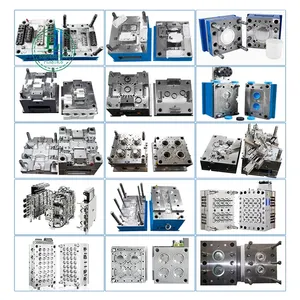

Moulds

Machining Services

Other Fabrication Services

Casting Services

Sheet Metal Fabrication

Forging Services

About products and suppliers

Exploring the Versatility of Casting Moulds

Casting moulds are pivotal in the manufacturing sector, serving as the foundational tools for shaping materials into precise geometries. These moulds cater to a diverse range of industries, from automotive to consumer goods, facilitating the production of both intricate components and large-scale items. The versatility of mould for injection moulding and metal mould casting processes underscores their importance in modern manufacturing.

Types and Applications of Casting Moulds

The application of casting moulds spans various methods such as green sand mold casting, plaster mold casting, and aluminium die casting mould techniques. Each method employs a unique approach to create components, whether it's for creating resilient machine parts using aluminum die cast mold or intricate art pieces through resin casting molds. Industries ranging from medical to aerospace rely on these methods for their product development.

Material Considerations in Mould Design

Selecting the appropriate material for a casting mould is crucial for achieving the desired product quality and longevity of the mould itself. Options include robust iron molds for heavy-duty applications or silicone moulds for resin when flexibility and fine detail are required. The choice of material impacts the mould's performance, cost-effectiveness, and the quality of the final product.

Features and Advantages of High-Precision Moulds

High-precision moulds, such as those used in plastic injection moulding company operations, offer numerous advantages. They provide repeatability, accuracy, and the ability to produce complex shapes with fine details. The strategic design of these moulds can also lead to cost savings by standardizing components for ease of use and compatibility across various projects.

Optimizing Production with Casting Moulds

Incorporating casting moulds into production lines can significantly optimize manufacturing processes. For instance, injection moulding companies leverage the efficiency of moulds to minimize cycle times and maximize output. The adaptability of moulds to different materials and designs makes them a valuable asset for businesses looking to streamline their production capabilities.

Choosing the Right Mould for Your Project

Selecting the right casting mould requires careful consideration of the design, material, and intended use. Platforms like Alibaba.com facilitate this selection by connecting buyers with a plethora of suppliers, each offering a range of moulding and casting solutions. Whether it's for wax mold casting or intricate plastic injection mould applications, the right partnership can lead to successful project outcomes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4