Popular in your industry

Top categories

About cast iron balls

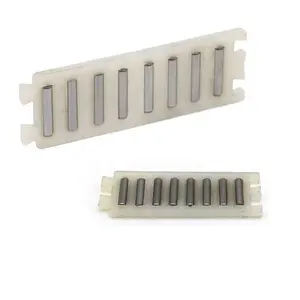

Understanding Cast Iron Balls

Cast iron balls are a fundamental component in various industrial processes, known for their durability and versatility. These spherical devices are typically used in milling and grinding operations, where they pulverize materials to fine powders. Their application extends to industries such as mining, cement production, and coal grinding. The composition of these balls usually includes carbon and silicon, which contribute to their high wear resistance and toughness.

Types and Applications

There are several types of cast iron grinding balls, each suited to specific grinding tasks. High-chrome media are often employed in cement mills, while low-chrome options are more common in utility industries. The size and hardness of the balls can be varied according to the milling requirements, with larger, harder balls being used for coarser grinding and smaller ones for finer grinding tasks.

Features and Materials

The features of cast iron grinding media are closely linked to their material composition. High-carbon varieties offer superior strength, making them ideal for high-impact applications. On the other hand, low-carbon balls provide better surface finishes, which is crucial in certain manufacturing processes. The choice of material impacts the ball's performance, including its wear rate, impact resistance, and the quality of the product being milled.

Advantages of Cast Iron Balls

The advantages of using cast iron balls in industrial processes are manifold. Their robust nature means they can withstand high-pressure environments and repetitive impacts without significant degradation. This longevity ensures consistent performance over time, reducing the need for frequent replacements and thus minimizing downtime. Additionally, their ability to be recycled makes them an environmentally friendly option for milling operations.

Manufacturing Techniques

The manufacturing of cast iron balls involves both casting and machining to achieve the desired precision and surface finish. The casting process ensures the economical production of complex shapes, while subsequent machining refines the product to meet specific tolerances. This combination of processes ensures that the final product can meet the rigorous demands of industrial applications.

Choosing the Right Cast Iron Balls

Selecting the appropriate cast iron balls for a given application requires consideration of the material to be milled, the milling environment, and the desired outcome. Alibaba.com hosts a vast array of options, allowing buyers to find the exact specifications they need for their operations. With a focus on connecting buyers with a diverse range of suppliers, the platform facilitates the sourcing of these essential components for businesses worldwide.