Introduction to Carton Paper Tube Machinery

The carton paper tube machine is an essential piece of equipment in the packaging industry, designed for the production of robust and versatile paper tubes. These machines are integral in creating cylindrical paper tubes used for a myriad of applications, from industrial packaging to consumer goods.

Types and Configurations

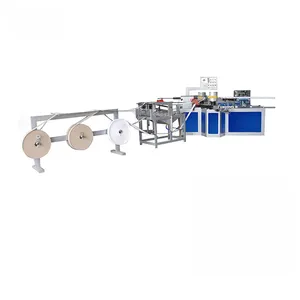

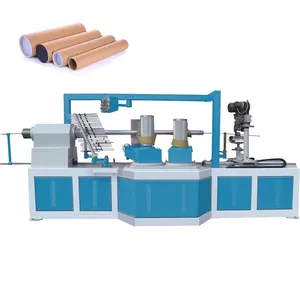

There are various types of paper tube machinery, each tailored to specific production needs. Some are designed for heavy-duty output, creating thick-walled tubes for construction or postal services, while others focus on thinner, more precise tubes for retail packaging. The configurations range from semi-automatic to fully automatic paper tube machines, offering solutions for businesses of all sizes.

Applications and Uses

The applications of paper tube making machines are extensive. The produced tubes serve as cores for winding textiles, papers, and metals, and as containers for consumer products like posters or yoga mats. In the industrial sector, these tubes are foundational for fabric rolls, tape rolls, and even material handling.

Features and Technical Specifications

A high-performance paper tube winder is characterized by its speed, efficiency, and the quality of tubes it produces. These machines typically feature advanced control systems for precise operation, adjustable mandrels for various tube diameters, and cutting systems for accurate length specifications. The durability of the machinery is paramount, often constructed with high-grade materials to withstand the rigors of continuous operation.

Materials and Sustainability

Most paper tube machines utilize a range of paper materials, including recycled paper, to produce eco-friendly tubes. The adaptability to different paper types is not only a testament to the machine's versatility but also its role in promoting sustainable production practices.

Advantages of Modern Paper Tube Machinery

Modern paper core making machines offer significant advantages, such as reduced labor costs due to automation and increased production speeds. The precision engineering behind these machines ensures minimal material wastage, contributing to cost-effectiveness and environmental conservation. Furthermore, the reliability of these machines means consistent production quality, which is crucial for maintaining industry standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4