Understanding Carburetor Floats

The carburetor float is an essential component in the fuel delivery system of many internal combustion engines. Typically found in classic motorcycles and older vehicle models, the carburetor float plays a pivotal role in maintaining the correct mixture of air and fuel, ensuring the engine runs smoothly. This introduction delves into the various aspects of carburetor floats, from their types to their applications and features.

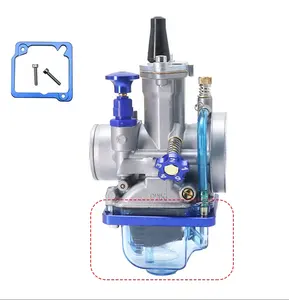

Types and Applications

Carburetor floats come in various materials such as brass, nitrophyl, and plastic. Each material offers distinct benefits, with brass being durable and resistant to corrosion, nitrophyl being lightweight and less susceptible to fuel varnish, and plastic being cost-effective and versatile. These components are crucial in environments where precise fuel metering is necessary, such as in motorcycle carburetors and vintage automotive systems.

Features and Advantages

The design of a carburetor float is critical as it must offer reliable buoyancy and adjust the fuel level accurately. A well-functioning float ensures that the engine receives a consistent fuel supply, contributing to optimal engine performance and efficiency. The advantages of a properly maintained carburetor float system include improved fuel economy, reduced emissions, and enhanced engine longevity.

Materials and Durability

When selecting a carburetor float, the material is a significant consideration. Brass floats are known for their robustness and long service life, while modern plastic and nitrophyl floats are designed for their resistance to ethanol and other chemicals found in fuels today. The choice of material affects the float's durability and performance in different operating conditions.

Selection Considerations

Choosing the right carburetor float involves understanding the specific requirements of your engine's fuel system. Factors such as float weight, size, and material compatibility with the fuel type are crucial. It is important to select a float that matches the specifications of the carburetor to prevent issues such as flooding or fuel starvation.

Maintenance Insights

Regular maintenance of the carburetor float is essential for the longevity of the fuel system. Inspecting the float for damage, ensuring it is free from leaks, and checking that it operates smoothly can prevent many common engine problems. While the carburetor float is a simple component, its condition is integral to the overall health of the engine's fuel delivery system.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4