Understanding Carbon Fiber Knitting Machines

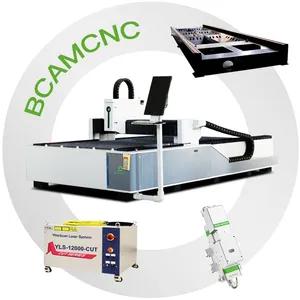

When delving into the realm of textile production, the carbon fiber knitting machine stands out as a specialized piece of equipment designed for creating high-strength fabric. These machines cater to a variety of production needs, from small-scale artisanal projects to large industrial endeavors. Understanding the capabilities and applications of these machines is crucial for manufacturers and designers alike.

Types of Carbon Fiber Knitting Equipment

The diversity of carbon fiber weaving equipment is vast, with each type serving a specific function. Inkle looms, for instance, are perfect for crafting narrow fabric strips, making them suitable for beginners and for producing items like belts and straps. For larger projects, floor looms are the go-to machines, capable of handling extensive and wide fabric production such as home linens and rugs. Table looms offer a balance between size and functionality, being compact enough for portability while still allowing for intricate pattern weaving. Lastly, the backstrap loom, a tool with ancient origins, continues to be used today for its simplicity and effectiveness.

Applications and Features

The application of a carbon fiber textile machine is not limited to a single end-product. These machines are versatile, enabling the creation of everything from high-fashion garments to industrial-grade materials. The features of these machines vary, with some offering computerized pattern capabilities, while others focus on manual control for a more hands-on approach. The common thread among all is their ability to work with carbon fiber, a material known for its strength, durability, and lightweight properties.

Selecting the Right Machine

Choosing the correct carbon fiber loom hinges on several factors. The weaver's experience level is paramount; beginners may favor simpler, more user-friendly looms, while seasoned weavers might opt for machines that offer more complex functionality. The intended fabric type also influences the decision—larger, more intricate patterns will require a more advanced loom. Additionally, the physical space available for the machine is a practical consideration, ensuring there is enough room for operation and material handling.

Advantages of Carbon Fiber Knitting

The use of a carbon fiber weaving loom brings with it a host of advantages. The resulting carbon fiber fabric is renowned for its exceptional strength-to-weight ratio, making it a sought-after material in various industries, including aerospace, automotive, and sports equipment. Moreover, the precision and efficiency of modern knitting machines allow for consistent quality and intricate designs that are difficult to achieve through other means.

Conclusion

For those in the market for a carbon fiber knitting machine, understanding the different types, applications, and features is essential. While the selection process can be complex, it is important to consider the level of expertise, intended fabric type, and available space. With a range of machines available, each offering unique benefits, manufacturers can find the right equipment to meet their production needs and capitalize on the advantages of carbon fiber textiles.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4