Understanding Cable Tray Elbows

Cable tray elbows are integral components in the management of cable systems, designed to guide and protect electrical wires and cables by allowing them to turn corners or change directions smoothly. These fittings are essential in creating a secure and organized pathway for cable systems in various settings.

Types and Applications

There are several types of cable tray elbows, including horizontal and vertical variations, each suited to different installation scenarios. Their applications are diverse, ranging from industrial environments to commercial buildings, where they facilitate the distribution of power and data cables while maintaining system integrity.

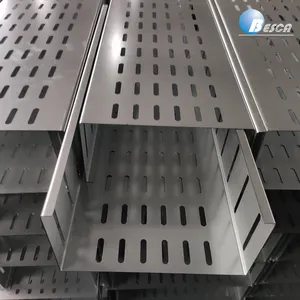

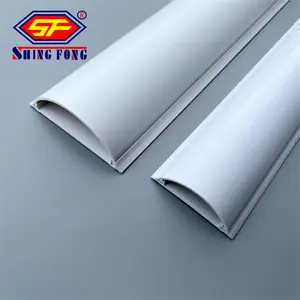

Features and Materials

The features of a cable tray elbow include its angle of turn, typically 90 degrees, but also available in 30, 45, and 60 degrees to navigate different layouts. Materials used in manufacturing these components vary, with options like galvanized steel, stainless steel, and aluminum, each offering distinct advantages in terms of durability and environmental resistance.

Advantages of Using Cable Tray Elbows

Utilizing cable tray elbows in cable management systems offers numerous benefits. They enhance safety by keeping cables organized and protected from potential damage. Additionally, they contribute to system flexibility, allowing for future expansion or reconfiguration with minimal disruption.

Customization and Compatibility

While standard cable tray elbows meet most needs, there is also the possibility of customization to address specific requirements. Compatibility with various cable tray types, such as ladder, solid-bottom, or trough, ensures that these elbows can be integrated into existing systems with ease.

Selection Considerations

When selecting a cable tray elbow, consider factors such as load capacity, environmental conditions, and material compatibility. Ensuring the right fit for the application not only extends the lifespan of the cable system but also maintains its performance and reliability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4