Understanding Cable Repairing Machines

When delving into the realm of cable repairing machines, it's essential to grasp the full spectrum of what these intricate devices entail. Designed to address the complexities of cable damage, these machines are pivotal in restoring the functionality of various types of cables.

Types and Applications

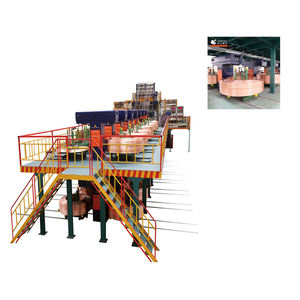

The diversity of cable manufacturing equipment spans across several categories, including machines tailored for large-scale, medium, and small wire production. Each class is further segmented into machines adept at handling either rough or fine wire constructions, ensuring that the specific needs of cable repair are met with precision. The application of these machines is vast, ranging from telecommunications to automotive industries, where the integrity of cable connections is paramount.

Material Considerations in Cable Repair

Selecting the appropriate wire processing machinery necessitates a thorough understanding of the material composition of the cables in question. Machines are often specialized to deal with specific materials, such as copper or aluminum, to ensure that the repair process aligns with the material properties and maintains the cable's integrity.

Features and Advantages

Modern wire repair equipment boasts features that enhance efficiency and precision. These include advanced diagnostic tools to detect faults and automated systems that ensure consistent quality in repairs. The advantages of utilizing such specialized machinery include extended cable life, reduced downtime, and the assurance that the repaired cables meet industry standards.

Space and Size Considerations

The physical dimensions of cable repair systems are a critical factor in the selection process. It's important that the chosen machine not only fits within the designated workspace but also allows for adequate operational space for technicians to perform repairs effectively.

Choosing the Right Cable Repairing Machine on Alibaba.com

Alibaba.com serves as a gateway to a vast selection of cable repairing machine options, connecting buyers with a multitude of suppliers. The platform facilitates the discovery of machines that align with buyers' specific requirements, without the constraints of time, thanks to its 24/7 operational model. While customization services are available, it is advised to engage with suppliers directly to discuss specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4