Understanding Crystalline Silicon

Crystalline silicon stands as a cornerstone in various industrial applications, particularly in the realm of electronics and solar energy. Its structured atomic arrangement grants it superior electrical properties, making it a sought-after material for precision tasks.

Types and Applications

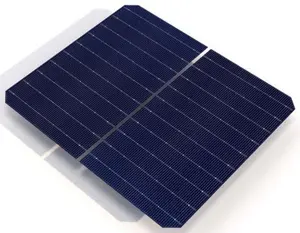

The versatility of crystalline silicon is evident in its types—monocrystalline and polycrystalline, each with distinct uses. Monocrystalline silicon, with its high purity, is ideal for solar panels and semiconductor devices. Polycrystalline silicon, while slightly less efficient, is used where cost-effectiveness is key.

Material Features and Advantages

The material composition of crystalline silicon includes a blend of silicon with other elements, creating a robust structure akin to quartz. Its resilience to high temperatures and chemical exposure makes it indispensable in manufacturing and automotive industries. Additionally, its low compression set is crucial for applications requiring shape retention after stress.

Manufacturing Process Insights

The manufacturing of silicone rubber involves a thermoset process, where a two-component solution is mixed and heat-cured. This process, often catalyzed by platinum, results in a finished product that meets stringent industrial requirements.

Selection and Customization

Alibaba.com hosts a wide array of silicone rubber materials, suitable for diverse industrial needs. These materials are available in various forms, including sheets that can be tailored to specific requirements. The durability and performance of these materials are noteworthy, as they are designed to withstand rigorous conditions without quality compromise.

Material Integrity and Performance

The crystalline silicon available on Alibaba.com is characterized by its resistance to corrosion and its robust nature. The materials, ranging from stainless steel to aluminum alloys, are treated to ensure longevity, including anodizing and powder-coating processes to enhance their resistance to environmental factors.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4