What is Butyl Rubber

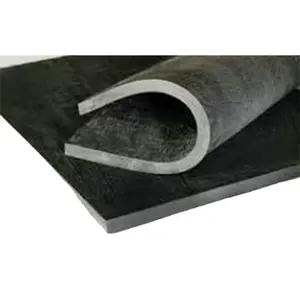

Butyl rubber, also known as isobutylene-isoprene rubber (IIR), is a synthetic rubber, a copolymer of isobutylene with isoprene. The primary qualities that make butyl rubber valuable are its exceptional impermeability to gases and its outstanding resistance to ozone, weathering, and chemicals. Due to these characteristics, it is widely used in applications requiring airtight and watertight seals. Butyl rubber has a low glass transition temperature, which ensures it remains flexible at lower temperatures, making it suitable for outdoor applications.

Industries ranging from automotive to construction and pharmaceuticals benefit from butyl rubber's properties. For instance, it's commonly used to manufacture inner tubes for tires due to its ability to hold air for prolonged periods. Its chemical resistance also makes it ideal for creating seals in chemical processing plants and pharmaceutical stoppers that prevent contamination. Moreover, butyl rubber is used in roofing materials for its waterproofing capabilities and in vibration damping products due to its energy-absorbing properties.

The functionality of butyl rubber depends on its unique molecular structure, which provides the material with low permeability to gases and moisture. The long polyisobutylene segments in its composition contribute to its flexibility and gas retention features, while the minor addition of isoprene allows it to be vulcanized (cured) with sulfur, enhancing its strength and elasticity. These principles enable butyl rubber to perform effectively across various demanding applications.

Types of Butyl Rubber

Butyl rubber comes in different types that cater to a variety of industrial needs. Here's a closer look at these types:

Regular Butyl Rubber: This is the most common form of butyl rubber with a balance of good impermeability and mechanical properties. It’s frequently used in tire inner liners, adhesives, and sealants.

Bromobutyl Rubber: By introducing bromine into the polymer chain during manufacturing, bromobutyl rubber is created with enhanced curing characteristics. It's often utilized in the pharmaceutical industry for items such as medicine stoppers due to its superior cleanliness and air-tightness.

Chlorobutyl Rubber: Similar to bromobutyl, chlorobutyl rubber is made by incorporating chlorine. It offers better resistance to heat and improved compression set characteristics suitable for high-temperature applications like automotive hoses.

Reclaimed Butyl Rubber: This type is recycled from post-industrial butyl rubber scrap, offering a more sustainable option. Its uses include creating eco-friendly roofing membranes and mats.

Each type serves distinct purposes based on their unique properties, making them indispensable for specific industrial uses.

How to Choose Butyl Rubber

Selecting the right kind of butyl rubber is crucial for businesses seeking materials that align with their application requirements. To make an informed decision:

Consider the application's exposure to chemicals or extreme temperatures; if it involves harsh conditions, bromobutyl or chlorobutyl rubbers might be more appropriate due to their enhanced resistances.

Assess the need for sustainability; if environmental impact is a concern, reclaimed butyl rubber could be the suitable choice as it reduces waste and often retains many of the original material’s properties.

Evaluate the necessity for gas impermeability; regular butyl is a reliable option for products like tire inner tubes where this feature is paramount.

By taking these factors into account alongside specific project requirements like flexibility or durability, businesses can pinpoint the type of butyl rubber best-suited for their particular industrial uses.

Best Butyl Rubber on Alibaba.com

For businesses around the globe looking for reliable suppliers of butyl rubber, Alibaba.com stands out as a premier online B2B marketplace. Alibaba.com connects you with numerous suppliers offering a wide range of butyl rubber types tailored to meet various industrial needs. Whether you're looking for regular butyl for general sealing purposes or specialized grades like bromobutyl or chlorobutyl rubbers for more demanding applications, you'll find suppliers who can cater to your specific requirements on this platform.

Alibaba.com understands the importance of quality and reliability in industrial materials. Hence, it emphasizes connecting buyers with suppliers who uphold high standards of product excellence. With services such as Trade Assurance, your transactions are protected, ensuring you receive what you have ordered within the stipulated time frame.

Furthermore, Alibaba.com simplifies international trade by providing tools that assist buyers in navigating through vast selections and communicating effectively with suppliers regardless of language barriers. This commitment to facilitating smooth trade transactions makes Alibaba.com an ideal destination for sourcing butyl rubber efficiently and confidently.

Common FAQs for Butyl Rubber

What is butyl rubber primarily used for in industrial applications?

Butyl rubber is widely utilized for its excellent air and moisture impermeability, making it ideal for industrial applications such as tire inner liners, seals in chemical processing, pharmaceutical closures, and waterproof roofing materials.

How does butyl rubber's chemical resistance benefit the pharmaceutical industry?

Its resistance to acids, bases, and other aggressive chemicals ensures that pharmaceutical products remain uncontaminated, which is why butyl rubber is often chosen for stoppers and seals in medication vials and containers.

In what temperature range does butyl rubber maintain its flexibility?

Butyl rubber maintains its flexibility over a broad temperature range due to its low glass transition temperature, performing well in both hot and cold environments.

Are there eco-friendly options available in butyl rubber?

Yes, reclaimed butyl rubber is available as an eco-friendly option, reprocessed from industrial scrap while retaining many beneficial properties of the original material.

Can butyl rubber be customized according to specific business requirements?

Suppliers can provide processing services such as moulding, cutting, and custom fabrication to meet specific business needs for butyl rubber applications.

What types of butyl rubber are best suited for outdoor applications?

Regular butyl rubber with its waterproof and weather-resistant properties is commonly used; however, for more demanding outdoor applications involving higher temperatures or UV exposure, chlorobutyl or bromobutyl may be more appropriate.

How do I ensure the butyl rubber I order meets my application's specifications?

When sourcing from suppliers on platforms like Alibaba.com, ensure to discuss your application's specifications in detail and request samples if possible to test the material's suitability before placing a bulk order.

Are there any particular design styles that butyl rubber is compatible with?

Butyl rubber is versatile and can be incorporated into various design styles including modern, traditional, industrial, and contemporary applications due to its functionality and adaptability.

How does bromobutyl differ from regular butyl rubber?

Bromobutyl rubber has enhanced curing characteristics due to the presence of bromine in its composition, offering better cleanliness and air-tightness which are crucial for pharmaceutical applications.

What should I consider when using butyl rubber for vibration damping purposes?

Consider the specific vibration frequency and amplitude you need to dampen; butyl rubber can absorb energy effectively, making it suitable for use in vibration damping products like pads or mounts.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4