Bubble Tissue Paper: An Overview

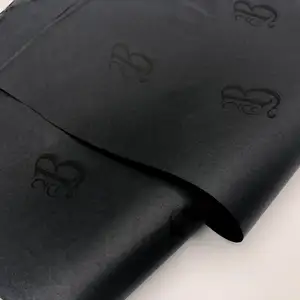

Bubble tissue paper, a versatile packaging material, is widely utilized across various industries for its protective and cushioning properties. This specialty paper is a hybrid of the lightweight nature of tissue paper and the protective bubbles found in bubble wrap, offering a unique solution for delicate items.

Types and Materials

The market offers an array of bubble tissue paper types, each tailored to different packaging needs. Options range from kraft paper-backed varieties to those combining wood pulp and mixed pulp materials. The selection is diverse, with some papers featuring chemical-mechanical pulp, while others rely on purely mechanical or chemical pulp processes.

Applications and Uses

Bubble tissue paper's primary use is to safeguard fragile items such as crafts, fur, and photo frames during transit. Its application is not limited to these; it's also suitable for a broad spectrum of products needing extra care against impacts or scratches.

Features and Advantages

This packaging material stands out for its lightweight yet robust protective features. It absorbs shocks and prevents damage to delicate surfaces, ensuring items arrive in pristine condition. The combination of tissue and air-filled bubbles provides a balance of protection without adding significant weight, which is crucial for shipping cost management.

Environmental Considerations

Eco-conscious businesses may opt for bubble tissue paper made from recycled materials, reducing the environmental footprint. The industry is increasingly moving towards sustainable practices, offering products that do not compromise on protection while being kinder to the planet.

Choosing the Right Bubble Tissue Paper

Selecting the appropriate bubble tissue paper involves considering the item's fragility, weight, and size. It's essential to match the paper's properties, such as pulp type and bubble size, to the product's specific needs to ensure optimal protection.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4