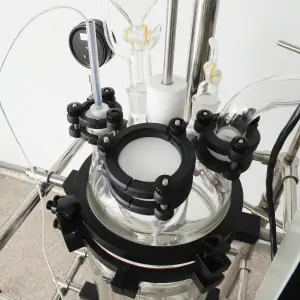

Discover the Versatility of Biodiesel Reactors

Biodiesel reactors are pivotal in the sustainable energy sector, facilitating the conversion of biomass into biodiesel fuel. These reactors are integral for industries aiming to produce renewable energy while minimizing environmental impact. This introduction delves into the various aspects of biodiesel reactors, including types, applications, and features.

Types of Biodiesel Reactors

The market offers diverse types of biodiesel reactors, each tailored to meet specific production needs. The ultrasonic biodiesel reactor is a notable example, utilizing ultrasonic waves to enhance the transesterification process, leading to faster reaction times and improved yield. Another variant, the biodiesel reactor kit, provides a more compact solution for smaller-scale or experimental biodiesel production, allowing for flexibility and ease of use.

Applications and Features

Biodiesel reactors are not limited to fuel production; they serve various sectors, including water treatment and filtration. The features of these reactors are designed to ensure efficiency and safety. Advanced safety features protect operators from potential hazards and prevent contamination of reactants. Energy efficiency is a hallmark of these systems, with designs focused on reducing electricity consumption and operational costs.

Materials and Advantages

Constructed from robust materials, biodiesel reactors are built to withstand the rigors of continuous operation. The materials are chosen for their durability and compatibility with the chemical processes involved in biodiesel production. The advantages of using these reactors are manifold, including their contribution to reducing reliance on fossil fuels and their role in promoting sustainable energy practices.

Challenges in Supply and Demand

Despite the high demand for biodiesel reactor products, the industry faces challenges such as supply delays and manufacturing bottlenecks. However, Alibaba.com serves as a bridge, connecting buyers with experienced wholesalers who can navigate these complexities and ensure the timely provision of essential biodiesel reactor supplies.

Choosing the Right Biodiesel Reactor

Selecting the appropriate biodiesel reactor involves considering the specific requirements of your production process. Factors such as the scale of production, the desired efficiency, and the type of biomass to be processed are crucial. For those involved in ultrasonic reactor biodiesel production, the choice will differ from those requiring a standard reactor setup. While Alibaba.com does not endorse or guarantee specific products, the platform offers a comprehensive range of options to cater to various needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4