Bending According To Customer Requirements Customized Hardware Joint Stamping Bending Process Accessories

Bending 200t4100 Hydraulic Sheet Machine Sheet Metal Bending Machine Price Da69t Cnc Hydraulic Press Brake Machine With 6+1 Axes

Bending CNC Hydraulic Bending Machine Sheet Metal DA66T System Press Brake

Bending AMADA Type High Quality MB8 125Ton*3200 Cnc Press Brake Stainless Steel CNC Bending Machine

Bending MB8 200T/4100 8+1 Axis CNC Sheet Metal Bending Machine DA69T Hydraulic CNC Press Brake

Bending Press Brake WC67K Series 100 Ton 3200 10 Feet Sheet Metal Bending Machine NC CNC Hydraulic Press Brake

Manual Metal Sheet Folding Machine For Cutting And Bending

Tube Bended CNC Bending Machining Custom Stainless Steel Tube Bend

Portable Bench Top Sheet Metal Hand Brake 20Gauge Bender Up to 90 Degree Heavy Duty Bends

5/8 Inch Electric Rebound Pipe Bender 16mm Portable Hydraulic Electric #5 Rebar Bender For Bending Over Steel Rod 110V 220V

Manual sheet metal press brake folding machine for sale bending

China reliable Durmark sheet metal manual folding machine/stainless steel bender/press brake your ideal solution for bending

hydraulic multifunctional busbar multi-working processing machine ztmx 503 bending

Automatic Pipe Bender Lron And Aluminum Round/Square Pipe Bender Pipe Bende

Four Column Hydraulic Machine Model Y32 With Stamping, Bending, Turning-Up And Extending

Manual tools for the bending, shearing, rolling on one supertech machine, 3-in-1, 1320mm 1.5mm metal sheet, workshop used

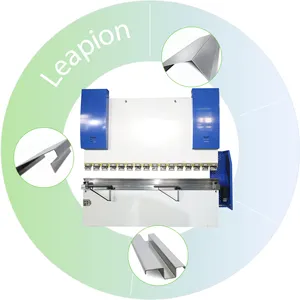

New style cnc press brake and bending machine for sheet metal processing

Dapeng Industry Equipment MG3512 35t 1200mm MINI Metal Steel CNC Bending Machine Hydraulic Press Brake

250T/3200 bending machines Hydraulic CNC bending machine and Standard press brake with DA53T controller

Minnuo approvedautomatic hydraulic press brake made in Minnuo for iron steel bending

Steel Metal Mandrel Hydraulic CNC 38 Square Pipe And Tube Bending Machines Price

Small Manual Bending Machine Hydraulic Press Brake For manufacturer

DXTECH 80T/2000mm CNC Press Brake hydraulic metal sheet plate iron bending machine

Fully Automatic 100t/4000mm Sheet Metal Bending Press Brake Machine For Metalworking

Wide Working Table Press Brake 200t/5000mm Steel Bending Machine For Precision Instruments

European Standard Sheet Metal CNC Press Brake Hydraulic Bending Machine Manufacturer

Automatic Integrated Metal Rule Die Steel Knife Bend Bending Machine Auto Knife Sheet Blade Bender Cutting Machine Price

Mini CNC hydraulic metal plate 30 ton 1600 mm small sheet bending machine metal working press brake 63T 3200mm

2019 3mm manual sheet metal bending machine

Huth hb10 exhaust bender pipe tube bending machine 6001

Full-automatic steel bar bending machine Round bar bender Stirrup bending machine

Machine Plate Bender for Sheet Metal Working Metform Manual Sheet Bending Folding Provided 80 Manual Press Brake Machine 150 540

Manufacture Sells DW89NC Hydraulic Semi Automatic Mandrel Pipe and Tube Bending Machine for Furniture Exhaust

8 MM 250 Ton Metal Sheet Plate Automatic CNC Hydraulic Press Brake Bender Bending Machine

DHY-150 three in one busbar punching bending cutting machine

Manual metal folding machine bending machine

MBP-301 Multifunctional Busbar Processing Cutting Bending Punching Machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4