Exploring Armature Winding Machines - Automated Armature Winding Systems

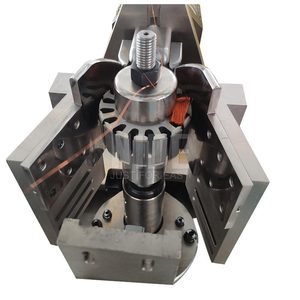

Armature winding machines are precision-engineered devices crucial for the production of armatures, key elements in electric motors. Serving a spectrum of sectors, from manufacturing facilities and machinery repair workshops to construction firms and DIY aficionados, these machines primarily wind wire around an armature core. This process generates a magnetic field that interacts with the stator windings of the motor to produce mechanical movement.

The operational principles of these machines are grounded in electromagnetism. An electric current through the armature winding induces a magnetic field, which, when coupled with the stator winding's field, propels the armature into rotation. The exactitude and efficiency of armature winding machines are indispensable for the optimal performance of motors, especially in industries heavily reliant on electric motors.

Armature winding machines boast a suite of features to guarantee a superior finished product. They are typically outfitted with multiple spindles to secure the armature during the winding process. The tension and velocity of the winding can be fine-tuned to meet the specifications of diverse armatures and winding patterns. Moreover, many machines incorporate tools such as wire cutters and formers to facilitate the armature winding preparation.

Varieties of Armature Winding Machines

Different types of armature winding machines are available to meet specific needs:

-

Manual Armature Winding Machine: This variant necessitates operator control and is commonly employed for limited production runs or in educational environments where practical experience is valued.

-

Automatic Armature Winding Machine: These machines perform winding operations with minimal human oversight, ideal for mass production settings where uniformity and efficiency are paramount.

-

Semi-automatic Armature Winding Machine: Combining manual and automated operations, these machines offer a compromise between operator engagement and productivity.

-

Fully Automatic Armature Winding Machine: Featuring advanced PLC controls, these units can execute complex winding sequences autonomously, crucial for extensive production demands.

-

Portable Armature Winding Machine: Tailored for field use, these compact and transportable machines are perfect for on-the-spot repairs or in settings where space is constrained.

Each machine category is tailored to particular scenarios, ranging from high-volume manufacturing plants to repair shops handling detailed motor restorations.

Selecting an Armature Winding Machine - Automated Armature Winding Systems

Choosing the appropriate armature winding machine is vital for attaining the desired production results while maintaining operational efficiency. Entities across various domains, such as manufacturing, construction, or machinery repair, should deliberate on multiple aspects prior to acquisition.

Initially, the complexity of the winding task should be evaluated. Basic tasks may only require a straightforward design, whereas complex armatures might necessitate a machine with multi-axis control and sophisticated capabilities. The type of material to be wound, whether steel, stainless steel, or another metal, also plays a role in this decision.

Secondly, production volume should be taken into account. Automated systems are beneficial in high-output settings, reducing downtime and enhancing throughput.

Thirdly, the scalability of the machine is important. Growing businesses may require winding machines that can adapt to broader product ranges or heightened demand without substantial new investments.

Lastly, the availability of after-sales support should be scrutinized. Ensuring that the provider can offer the necessary technical assistance and maintenance services is crucial for uninterrupted operations.

Discovering Armature Winding Machines - Automated Armature Winding Systems on Alibaba.com

Alibaba.com distinguishes itself as a premier global marketplace, linking businesses with an extensive selection of suppliers providing armature winding machines for diverse industrial uses. With over twenty years of experience in B2B commerce across various sectors, Alibaba.com has emerged as an indispensable tool for companies in search of specialized equipment like armature winding machines.

The platform's comprehensive inventory ensures that whether the search is for a semi-automatic system or a fully automated setup with multifunctional capabilities, Alibaba.com can likely match you with a supplier that fits your criteria. Additionally, services such as Trade Assurance offer added security by protecting payments until delivery satisfaction is confirmed.

For enterprises aiming to boost operational efficiency or those in pursuit of armature winding machines tailored to their unique requirements without sacrificing quality or dependability, Alibaba.com presents an unparalleled spectrum of choices. With global suppliers presenting their wares on this reputable platform, businesses can tap into international market prospects while benefiting from support services designed to simplify and streamline international trade.

Frequently Asked Questions for Armature Winding Machines - Automated Armature Winding Systems

What is the purpose of an armature winding machine?

Armature winding machines are primarily utilized in sectors that manufacture electric motors, generators, transformers, and other rotating machinery, where they are instrumental in winding the armature, a vital component of these devices.

How does an armature winding machine function?

An armature winding machine functions by rotating the armature core on a spindle while wire is methodically wound onto the core to form the windings, a process that is repeated to achieve the required number of windings.

What are the available types of armature winding machines?

Armature winding machines are available in various forms, including automatic, semi-automatic, and manual models, each offering differing degrees of automation and production capacities to suit a range of operational needs.

What considerations are important when selecting an armature winding machine?

In choosing an armature winding machine, factors to consider include the types of armatures to be wound, their dimensions and configurations, the materials they are composed of, the relevant industries, the availability of after-sales service, and your specific operational demands.

Are armature winding machines capable of handling different core materials?

Armature winding machines are engineered to accommodate a variety of core materials. Nonetheless, selecting a machine that is compatible with the specific material requirements of your armatures is essential for ensuring durability and peak performance.

Is it feasible to obtain a custom armature winding machine for specialized applications?

Indeed, numerous suppliers on Alibaba.com provide custom armature winding machines that can be configured to meet the particular operational and technical needs of specialized applications.

What kind of after-sales services are typically included with an armature winding machine purchase?

After-sales services for armature winding machines may encompass online support, video technical assistance, engineers available for overseas machinery servicing, field maintenance and repair services, and access to spare parts, contingent on the supplier's offerings.

How can I ensure that the armature winding machine I select adheres to industry standards?

To ensure compliance with industry standards for an armature winding machine, confirm that it meets the relevant certifications for your region, such as CE for Europe or UL for the United States.

What materials are commonly employed in the construction of armature winding machines?

Armature winding machines are typically constructed from sturdy materials like steel, stainless steel, and other metals to ensure the machine's endurance and longevity under continuous operation.

Is it possible to locate an armature winding machine suitable for home use on Alibaba.com?

Certainly, Alibaba.com offers armature winding machines that are appropriate for small-scale home use, often utilized for appliance repairs and characterized by their portability and user-friendly design.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4