Understanding Angle Grinder Blades

Angle grinder blades are essential components for various cutting tasks, designed to work seamlessly with your power tools. These blades come in a multitude of designs, each tailored for specific materials and cutting requirements. Whether tackling a construction project or shaping materials in a workshop, the right blade can significantly enhance efficiency and precision.

Types of Angle Grinder Blades

Carbide saw blades are engineered for precise and clean cuts across a range of non-ferrous metals and plastic objects. Their durability and sharpness cater to professionals requiring accuracy. For woodworking endeavors, tungsten carbide saw blades are the go-to choice, adept at handling various wood types, from hardwood to chipboard. In contrast, metal cutting circular saw blades are optimal for straight cuts, slicing through metal with ease and speed.

Applications and Features

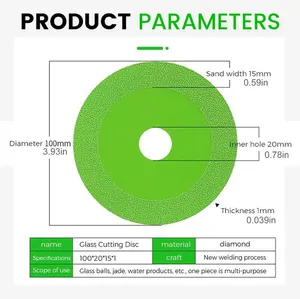

The versatility of angle grinder blades extends to their applications. For intricate work, such as watermarks and small shapes, scroll saw blades offer high precision. When it comes to cutting curves and cavities, the flexibility of reciprocating saw blades makes them a preferred option over their circular counterparts. For the toughest materials like stone, concrete, and ceramics, diamond saw blades stand out with their unmatched cutting capabilities.

Material Compatibility and Advantages

Selecting the appropriate angle grinder blade is crucial for both safety and project success. Diamond blades are renowned for their ability to cut through hard and abrasive materials without faltering, providing longevity and resilience. Carbide-tipped blades boast a balance of hardness and resistance to heat, ensuring clean cuts and reduced material waste. Each blade type brings its own set of advantages, from the flexibility of reciprocating blades to the precision of scroll saw blades.

Choosing the Right Blade

The decision on which angle grinder blade to select should be informed by the material you intend to cut and the desired outcome. For instance, blades designed for metal will differ from those meant for masonry in terms of tooth design and blade composition. Understanding the nature of the task at hand will guide you to the most suitable blade, ensuring that your cutting process is both effective and efficient.

Maintenance and Care

Maintaining your angle grinder blades is paramount to ensure their longevity and performance. Regular checks for wear and damage can prevent accidents and maintain the quality of cuts. Proper storage and handling are also essential, as is selecting the right blade for the right job, which can reduce the risk of premature wear.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4