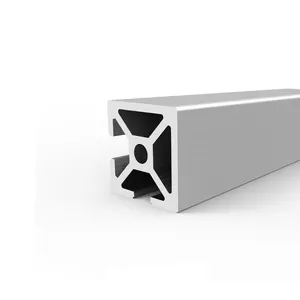

Exploring Aluminum Dovetail Extrusion Profiles

Aluminum dovetail extrusion profiles are a versatile and essential component in modern manufacturing and construction. These profiles are crafted through a process that pushes aluminum through a precision-designed die, resulting in a variety of cross-sectional shapes designed to interlock with ease. This method affords immense flexibility in design and application, making aluminum extrusions a go-to solution for a myriad of industries.

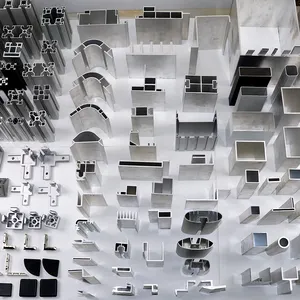

Types and Shapes of Aluminum Extrusions

The diversity of aluminum profile shapes caters to specific needs across different sectors. From L-angled brackets to T-shaped bars, each shape is engineered to provide structural integrity and ease of assembly. Specialized forms such as J caps, Z clips, and sliding track systems are also available, broadening the scope of potential applications. The adaptability of these profiles is further enhanced by the availability of solid round tubes and hollow tubes, offering a balance between strength and weight.

Material Specifications and Surface Treatments

Typically composed of 6000 series aluminum alloy, these profiles boast a temper range from T3 to T8, indicating the level of hardness and strength. The thickness of these profiles can vary from 0.2mm to a robust 20 mm, with customization options to meet specific requirements. Surface treatments such as anodizing, powder coating, and electrophoresis not only enhance the aesthetic appeal but also significantly improve the durability and corrosion resistance of the aluminum.

Applications and Features

Aluminum dovetail extrusion profiles are integral to industries ranging from automotive to construction. Their use in creating robust framing systems, intricate lighting fixtures, and reliable plumbing solutions underscores their versatility. The profiles' interlocking capabilities allow for innovative design solutions in office furniture and interior design, where both functionality and aesthetics are paramount.

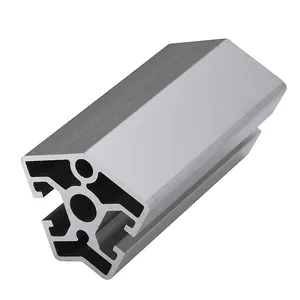

Advantages of Aluminum Extrusions

The advantages of using aluminum extrusion profiles are manifold. Their lightweight nature, coupled with high strength, makes them ideal for supporting structures while minimizing load. The ease of customization in terms of shape, size, and finish allows designers and engineers to tailor the profiles to their exact needs. Furthermore, the various surface treatments available extend the profiles' lifespan and enhance their appearance, with options like wood grain finishes providing a natural aesthetic without compromising on durability.

Choosing the Right Profile for Your Needs

Selecting the appropriate aluminum dovetail extrusion profile is crucial for ensuring the success of your project. Factors such as the intended application, environmental conditions, and mechanical requirements should guide your choice. With a comprehensive selection of profiles, the platform connects you with suppliers offering a range of extrusions to meet your project's specifications. Explore the options available to find the profile that aligns with your design and functional criteria.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4