Exploring the Versatility of Aluminum Armrest Profiles

Aluminum armrest profiles are integral components in various industries, serving as critical elements in construction, office furniture, and automotive manufacturing. These profiles are crafted from aluminum alloys, primarily from the 6000 series, known for their balance of strength and workability. The temper of these profiles typically ranges from T3 to T8, indicating the level of hardness and strength due to heat treatment processes.

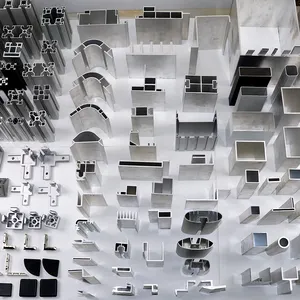

Types and Shapes of Aluminum Armrest Profiles

The diversity in the shape of aluminum armrest profiles is vast, with options including L-angled, square, and T-shaped bars. These profiles are not limited to solid forms; hollow tubes and intricate designs like J caps and Z clips are also available. This variety ensures that aluminum armrest profiles can be tailored to specific design requirements, whether for sleek office furniture contours or robust construction needs.

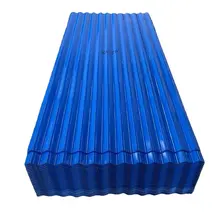

Surface Treatments and Finishes

Surface treatment options for aluminum armrest profiles are extensive, ranging from powder coating to anodizing. Each method offers unique benefits, such as improved corrosion resistance or aesthetic appeal. For instance, profile designs legacy ii aerobar may undergo sandblasting for a textured finish or electrophoresis for a glossy appearance. Wood printing is another innovative treatment, imparting a natural wood grain texture ideal for decorative applications.

Applications and Features

The application of aluminum armrest profiles spans across various fields. In the realm of interior design, profiles can be transformed into elegant lighting fixtures or part of a profile design legacy 2 aerobar. The automotive industry utilizes these profiles for components that require a blend of lightweight strength and precision. Plumbing and engineering sectors also benefit from the customizable nature of these profiles, which can be adapted to specific functional requirements.

Advantages of Aluminum Armrest Profiles

Aluminum armrest profiles offer several advantages, including their lightweight nature and resistance to corrosion, especially when treated with processes like PVDF coating or anodizing. The adaptability in terms of shapes and finishes, such as those seen in profile designs legacy ii aerobar, allows for a wide range of uses. Additionally, the ability to mimic textures, like wood, adds to their appeal in design-centric applications.

Customization and Color Variations

Customization is a key feature of aluminum armrest profiles, with the ability to adjust dimensions and thickness to meet specific needs. Surface treatments not only enhance durability but also allow for a spectrum of color options. Whether the requirement is for a subtle matte finish or a vibrant hue to complement a profile design legacy ii aerobar, these profiles can be tailored accordingly, without compromising on structural integrity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4