Introduction to Aluminium Seam Welding Machines

Seam welding stands as a pivotal fabrication process, essential for creating a continuous joint between two materials. An aluminium seam welding machine is a specialized piece of equipment designed to handle the unique properties of aluminium, ensuring a durable and consistent seam. This machinery is integral in industries where aluminium structures are paramount, including aerospace, automotive, and construction.

Types and Applications of Aluminium Seam Welders

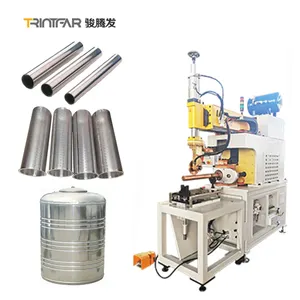

There are various types of seam welders tailored to different applications. Longitudinal welders, for instance, are adept at joining rectangular sections to fabricate extended lengths of material, such as pipes or ducts. On the other hand, resistance seam welders are the go-to machines for creating airtight joints in products like fuel tanks, where integrity is crucial. The versatility of an aluminium seam welding machine makes it suitable for a broad range of applications, from constructing aircraft fuselages to assembling intricate components in manufacturing lines.

Features and Materials

An aluminium seam welding machine is engineered to accommodate the conductivity and thermal properties of aluminium. These machines often feature precise heat control, robust construction, and compatibility with various aluminium alloys. The adaptability of these machines allows for their use with different thicknesses and grades of aluminium, catering to a wide spectrum of welding requirements.

Advantages of Using Aluminium Seam Welders

The use of an aluminium seam welding machine brings forth several advantages. It provides a uniform welding seam, crucial for structural integrity and aesthetic appeal. The efficiency of the process reduces material wastage and increases production speed, making it a cost-effective solution for large-scale operations. Furthermore, the automation capabilities of modern seam welders enhance precision and repeatability, which are essential for consistent quality in mass production.

Selection Considerations

When selecting an aluminium seam welding machine, it is important to consider the specific requirements of the task at hand. Factors such as the weld length, material thickness, and desired production speed play a significant role in determining the most suitable machine. Additionally, the choice between manual and automated systems will depend on the scale of operation and the level of precision required.

Conclusion

In conclusion, an aluminium seam welding machine is a critical investment for businesses that require efficient and reliable joining of aluminium components. With a range of machines available to suit various applications, industries can find the equipment that best meets their welding needs without compromising on quality or performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4