Introduction to Alcohol Production Equipment

The landscape of industrial alcohol production is intricate, necessitating specialized alcohol production equipment to meet the demands of efficiency and precision. This category encompasses a broad array of machinery designed for the various stages of alcohol production, from fermentation to bottling. Understanding the specific needs of your operation is crucial in selecting the appropriate equipment to optimize your production line.

Types of Alcohol Filling Machines

Within the realm of alcohol bottling equipment, there exists a diverse selection tailored to handle different materials and production scales. Key types include liquid filling machines for spirits and wines, powder filling machines for additives, and capsule fillers for specialized packaging needs. Each type is further segmented into manual, semi-automatic, and fully-automatic systems, addressing the spectrum of operational scales from boutique distilleries to large-scale producers.

Applications and Features

The application of commercial distilling equipment extends beyond merely filling containers. Advanced machines integrate capabilities such as precision weighing and vibratory mechanisms, particularly beneficial for managing powders and granulated additives. For high-viscosity alcohols or mixtures, positive displacement pump fillers offer a solution for efficient handling of creams, pastes, and gels, ensuring consistency and quality in the final product.

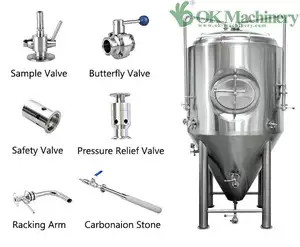

Material Considerations in Equipment

Selecting the right materials for distillery equipment is vital for maintaining product integrity and ensuring longevity of the machinery. Stainless steel is a prevalent choice due to its resistance to corrosion and ease of cleaning, a critical factor in alcohol production where hygiene and purity are paramount.

Advantages of Automated Filling Systems

Automation in brewery equipment presents numerous advantages, including enhanced production speed, improved accuracy, and reduced labor costs. Fully-automatic systems are particularly beneficial for large-scale operations, where they contribute to a streamlined process that manual labor cannot match. Even for smaller producers, semi-automatic systems can provide a significant upgrade from manual methods, balancing cost with increased efficiency.

Selecting the Right Equipment

When choosing the right alcohol manufacturing equipment, it is essential to consider the specific requirements of your production process. Factors such as production volume, container types, and the physical properties of the alcohol or additives being processed will guide the selection of the most suitable machinery. Alibaba.com offers a comprehensive range of equipment to cater to the diverse needs of the alcohol production industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4