Floating boat salvage rubber scrap for ship launching airbag for sales airbag 3l# natural rubber material import tailand

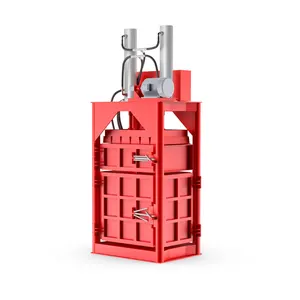

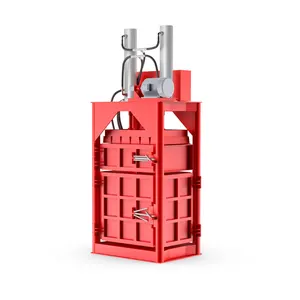

Vertical Hydraulic Cardboard Box Baling Press Waste Paper Baler Machine For Sale Balers Wast Plastic Compactor

Airbag scrap, a significant byproduct of the automotive industry, encompasses materials primarily derived from end-of-life vehicles. This category includes not only the airbag itself but also the associated components such as sensors and inflators. The recycling of airbag scrap is crucial for sustainable manufacturing practices, as it involves the recovery of valuable materials and the reduction of waste.

The types of airbag scrap can be categorized based on the materials they are made from, such as nylon airbag fabric scrap and plastic components. These materials find new life in various applications, ranging from the creation of recycled textile products to the manufacturing of plastic goods through processes like crushing and pelletizing.

Processing airbag scrap efficiently is key to unlocking its potential. The machinery used for this purpose is designed to handle the specific characteristics of airbag materials, such as durability and resistance to high temperatures. The advantages of processing airbag scrap include the conservation of resources, reduction of landfill waste, and the opportunity to tap into a market of recycled materials.

The primary material in airbag scrap is often nylon, known for its strength and elasticity. By recycling nylon airbag fabric scrap, the industry contributes to a circular economy, minimizing the environmental footprint of both the automotive and manufacturing sectors.

Selecting the appropriate machinery for airbag scrap processing is crucial. Equipment designed for this purpose should cater to the specific needs of handling robust materials like nylon airbag fabric scrap. The right machinery can significantly enhance the efficiency of the recycling process, ensuring that the recovered materials are of a quality that is suitable for reuse.

The recycling of airbag scrap aligns with global efforts to promote environmental sustainability. By repurposing airbag scrap, businesses contribute to waste reduction and resource conservation. Furthermore, compliance with industry standards and certifications, such as ISO and CE, underscores the commitment to environmental stewardship and quality assurance.