Understanding Automated Guided Vehicles (AGVs)

Automated Guided Vehicles, commonly known as AGVs, represent a transformative category in material handling and logistics. These self-guided vehicles are designed to transport materials around a manufacturing facility or warehouse without the need for manual intervention. The integration of AGV systems into industrial environments marks a significant leap towards efficiency and automation.

Types and Applications of AGVs

The types of automated guided vehicles vary, ranging from AGV forklifts to tuggers and unit load carriers. Each type serves a specific purpose, such as the AGV forklift, which is tailored for lifting and moving pallets, while tuggers are ideal for towing loads. These vehicles are integral to sectors like automotive, manufacturing, and AGV logistics, where they streamline processes and enhance workflow.

Features of AGV Technology

AGVs are equipped with various sophisticated features such as sensors, cameras, and navigation systems. An AGV system typically includes a software interface that allows for real-time tracking and management of the vehicles. This technology ensures that AGVs operate efficiently within the complex environments of warehouses and production facilities.

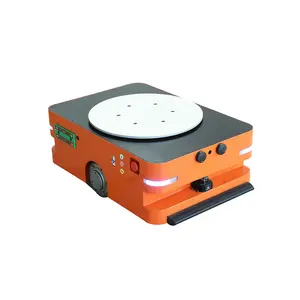

Materials and Construction

The construction of AGVs involves robust materials that can withstand the rigors of industrial use. Materials range from high-grade metals for structural components to advanced thermoplastics for casing. This ensures that AGVs can operate in different environmental conditions without compromising performance.

Advantages of Implementing AGVs

The adoption of automated guided vehicles offers numerous advantages, including increased safety due to reduced human intervention in material transport. Furthermore, AGVs contribute to enhanced precision in operations, leading to reduced waste and improved inventory management. The efficiency of AGV warehouse systems also translates to energy savings and lower operational costs.

Selecting the Right AGV for Your Needs

When considering the implementation of an AGV project, it is crucial to understand the specific needs of your operation. Factors such as load capacity, navigation technology, and the type of materials to be handled should guide the selection process. Engaging with experienced AGV manufacturers can provide insights into the best solutions for your application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4