A Comprehensive Guide to Absorption Towers

Absorption towers are pivotal components in various industrial processes, particularly in the realms of waste treatment, gas filtration, and air purification. These structures, also known as gas absorption columns, play a crucial role in removing contaminants from gaseous emissions, ensuring compliance with environmental standards and worker safety.

Types and Applications of Absorption Towers

The industrial landscape utilizes a variety of absorption towers, each designed to cater to specific needs. Packed bed absorption towers are widely employed due to their efficiency in handling gas-liquid absorption processes. Industries ranging from chemical manufacturing to waste management make use of packed tower absorbers to control emissions of toxic gases. In the realm of chemical production, absorption tower sulphuric acid plants and nitric acid absorption towers are specialized equipment designed for handling highly corrosive substances.

Design Features and Materials

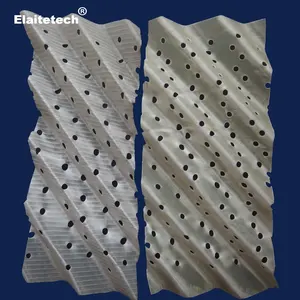

The design of an absorption tower is critical to its function. Plate tower for gas absorption and tray tower absorber designs are common, featuring plates or trays that increase contact between the gas and the liquid for more effective absorption. Materials used in construction, such as high-grade metals and alloys, are selected for their durability and resistance to corrosion, ensuring the longevity of the towers even in harsh industrial environments.

Advantages of Modern Absorption Towers

Modern absorption towers, including plate absorption columns and packed absorption towers, are engineered for maximum efficiency and minimal environmental impact. They boast advanced features like high-capacity fans and proprietary impeller designs that enhance performance while reducing noise and preventing sparks. The versatility of these towers is evident in their ability to handle a wide range of toxic gases, making them indispensable in industries committed to pollution control.

Understanding the Packing Factor

The efficiency of an absorption process can be significantly influenced by the packing factor absorption column. This factor takes into account the surface area of the packing material within the column and its resistance to gas flow. A well-designed packing factor ensures optimal contact between the gas and the liquid, leading to more effective absorption.

Choosing the Right Absorption Tower

Selecting the appropriate absorption tower for industrial use requires careful consideration of the specific gases to be treated and the desired efficiency of the process. Whether it's a packed tower gas absorption system or a plate tower absorption setup, the right choice will contribute to a safer and cleaner production environment. While Alibaba.com does not endorse any particular product, the platform offers a diverse array of options to meet the needs of various industries.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4