Exploring the Versatility of Abrasive Flap Wheels

Abrasive flap wheels are essential components in the realm of surface finishing and material removal. These tools, designed with a series of flaps radiating from a central hub, offer a unique combination of flexibility and effectiveness for a variety of applications. The flap wheel is distinguished by its ability to conform to the shape of the workpiece, providing a uniform finish and facilitating the operator's control over the finishing process.

Types and Applications

The utility of flap wheels extends across numerous industries, from metal fabrication to woodworking. Flap discs for metal are particularly valued for their aggressive cutting action and durability, making them suitable for grinding and finishing metal surfaces. Woodworkers often turn to flap sanding wheels to achieve a smooth, refined finish on wooden substrates. The adaptability of these tools allows for their use with a range of equipment, including flap wheel for drill and flapper wheel for angle grinder, ensuring that there is a flap wheel available for virtually any application.

Features and Materials

A key feature of the abrasive flap wheel is its construction. The flaps are typically made from abrasive materials such as aluminum oxide or zirconia alumina, attached to a sturdy hub. This design enables the wheel to wear away gradually, continually exposing fresh abrasive surfaces. This self-renewing capability ensures consistent performance and a longer lifespan than traditional sanding methods. Additionally, the density of the flaps can vary, providing options for more aggressive cutting or finer finishing, depending on the need.

Advantages of Using Flap Wheels

The advantages of using flap wheels are manifold. Their design allows for effective surface contact, reducing the effort required for tasks such as deburring, edge blending, or surface preparation. The flexibility of flap discs also minimizes the risk of gouging the workpiece, promoting a safer and more controlled abrasion process. Furthermore, the variety of sizes available, such as the 4 flap disc or the flap wheel 4 inch, ensures that there is a flap wheel to fit any tool or application.

Choosing the Right Flap Wheel

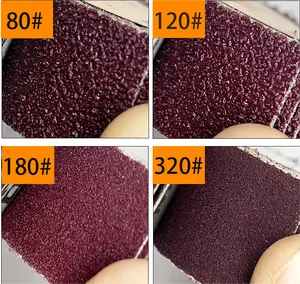

Selecting the appropriate flap wheel for a given task involves considering the material being worked on, the desired finish, and the compatible equipment. For intricate or detailed work, a dremel flap wheel might be the best choice, while larger scale operations might benefit from a robust flap disc for grinder. It is also important to match the grit size of the flap sanding disc to the specific requirements of the project for optimal results.

Conclusion

In conclusion, the abrasive flap wheel category offers a versatile and efficient solution for a multitude of surface finishing challenges. With a broad range of types and sizes, such as the flap disc wheel and flap disc for dremel, these tools are indispensable for professionals seeking precision and ease in their work. For those in search of reliable abrasive tools, the expansive selection on Alibaba.com caters to every need without compromise.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4