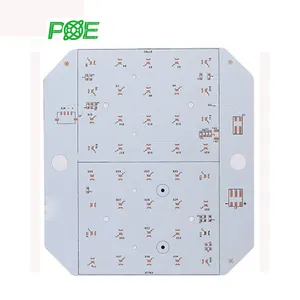

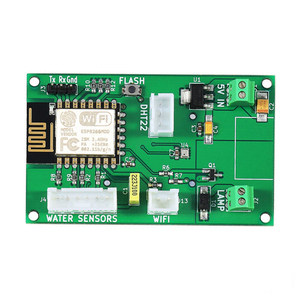

Alibaba.com showcases a diverse range of 94v0 LED PCB boards designed to cater to various lighting applications. Among the offerings, customers can find custom LED bulb PCB boards with a 94v0 aluminum base, suitable for products like LED flashlights and touch light lamps. These boards are tailored to provide a robust foundation for LED lighting solutions. Additionally, the platform features Shenzhen-manufactured printed circuit boards, emphasizing custom LED light PCB driver boards that comply with the 94v0 OEM design standards. For those seeking multilayer options, FR4 94v0 PCBs with multiple layers and chemical gold finishing are available, indicating a focus on durability and conductivity.

For specialized applications, there are high-power aluminum LED round PCBs that operate at 220V, suitable for demanding environments. The 94v0 certification ensures that these PCBs meet stringent safety and flammability standards. Furthermore, innovative designs like custom 94V0 LED light PCB circuit boards with integrated USB ports offer versatility for various electronic devices. The range extends to single-layer LED diode boards, which provide a cost-effective solution for simpler lighting systems.

Professional-grade LED grow light PCB module boards are also featured, catering to the agricultural industry's need for reliable and efficient plant growth lighting. For those requiring robust designs, double-sided multilayer PCB boards customized to specific requirements are listed, demonstrating the platform's capability to supply products for complex electronic needs. Lastly, high-power LED light driver PCBs, including COB and DOB LED bulb metal core circuit boards, are part of the selection, highlighting the availability of advanced components for high-intensity lighting systems.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4